Bosch is a multinational technology and engineering company that is based in Gerlingen, Germany. The corporation was founded by Robert Bosch, who named 92% of the company shares to Robert Bosch Stiftung Charity. The charity is focused on scientific and cultural discoveries that help continue the work of Robert Bosch. Bringing forward cutting-edge solutions that can easily be incorporated into everyday designs. One that offers users a pleasant experience, while making sure you leave a positive mark on the world.

Offering a wide range of appliances the Bosch name covers airport facilities, commercial buildings, the entertainment sector, the automotive industry, train stations, hotel facilities, and mining facilities. Additionally, the company only focuses on home appliances, power tools, and vehicles that change the way of our world.

Bosch might be a high-ranking company, but from time to time customers have complained about system errors. Fortunately, most of these errors can be fixed on your own. So rather than ignoring the error codes, your appliance is showing its time to note down the Bosh air conditioner error code and get to the bottom of the problem. To help you out we have listed down the most common error codes of Bosh air conditioners.

Codes List

| Error Codes | Solutions |

|---|---|

| E0 | Indoor unit EEPROM parameter error |

| E1 | Indoor / outdoor units communication error |

| E2 | Zero-crossing signal detection error |

| E3 | Indoor fan speed has been out of control |

| E4 | Indoor room temperature sensor T1 open circuit or short circuit |

| E5 | Evaporator coil temperature sensor T2 open circuit or short circuit |

| E6 | Indoor-Outdoor Unit Communication |

| EC | Refrigerant leakage detection |

| F0 | Overload current protection |

| F1 | Outdoor ambient temperature sensor T4 open circuit or short circuit |

| F2 | Condenser coil temperature sensor T3 open circuit or short circuit |

| F3 | Compressor discharge temperature sensor T5 open circuit or short circuit |

| F4 | Outdoor unit EEPROM parameter error |

| F5 | Outdoor fan speed has been out of control |

| P0 | IPM malfunction or IGBT over-strong current protection |

| P1 | Over voltage or over low voltage protection |

| P2 | High temperature protection of IPM module or compressor top |

| P3 | Outdoor ambient temperature too low |

| P4 | Inverter compressor drive error |

| P5 | Indoor units mode confl ict (multi-zone ONLY) |

| P6 | Compressor low-pressure protection |

| 21 | DC Peak (IPM Fault). IPM = Intelligent Power module. Restart 10x/hour, then blocked. Compressor broken or too much refrigerant in compressor. |

| 22 | CT 2 (Max CT). Restart after problem has vanished. Inverter current > 14 A. |

| 23 | DC Link Voltage is low or high. Restart after problem has vanished. Direct voltage 1~: <140 VDC or >480 (3kW: 420) VDC 3~: <320VDC or >780VDC. |

| 26 | Problem in DC Compressor positioning. Restart 10x/hour, then blocked. Wrong orientation of compressor connections (UVW). |

| 27 | PSC Fault. Restart 10x/hour, then blocked. High current IGBT (check reactor). |

| 29 | High current at Compressor phases. Restart 10x/hour, then blocked. |

| 32 | Temperature at discharge-pipe is too high. Restart after problem has vanished. Hot gas temperature TH5 >105 °C (check refrigerant load). |

| 35 | Low Pressure error. Restart 3x/hour, then blocked. Low Pressure < 0 kPa ( – 49.5 °C). |

| 41 | Problem in discharge-pipe temperature sensor. Direct shut-down. Sensor TH5 broken (200k ohm >25 °C). |

| 43 | High-pressure sensor (Open/ Short). Direct shut-down. LP/HP sensor broken. |

| 44 | Problem in ambient temperature sensor. Direct shut-down. Sensor TH7 broken (10k ohm >25 °C). |

| 45 | Problem in condenser-middle-pipe temperature sensor. Direct shut-down. Sensor TH8 broken (5k ohm >25 °C). |

| 46 | Problem in suction-pipe temperature sensor. Direct shut-down. Sensor TH4 broken (5k ohm>25 °C). |

| 48 | Cond. Out-pipe Th Error (Open/ Short). Direct shut-down. Sensor TH6 broken (5k ohm>25 °C). |

| 52 | Bad communication between Inverter-PCB and Main-PCB. Restart 3x/hour, then blocked. Wiring between Mainboard and Inverter board damaged (3~ phase only). |

| 53 | Bad communication between CanPCB and Main-PCB. Direct shut-down. Wiring between Mainboard and CAN-PCB damaged. |

| 54 | Phase sequence incorrect. Restart 10x/hour, then blocked. only 2 phases or incorrect rotation field (3~ phase only). |

| 55 | CAN Communication error (CANPCB <=> Installerboard). Direct shut-down. Wiring between CAN-PCB and Indoor unit damaged. |

| 60 | EEPROM Checksum mismatched. Direct shut-down. Change EEPROM. |

| 61 | Temperature at condenser-pipe is too high. Restart after problem has vanished. Condensing temperature >65.3°C (4199 kPa) {Heating} Condensing temperature >64.2 °C(4101 kPa) {Cooling}. |

| 62 | Temperature at heat sink is too high. Restart after problem has vanished. Heat sink temperature >85 °C. |

| 65 | Problem in heatsink temperature sensor. Direct shut-down. Heat sink sensor / Inverter-PCB broke. |

| 67 | ODU BLDC fan lock. Restart 10x/hour, then blocked. Fan blocked. |

| CF | when anti-cold air feature is turned on |

| dF | when defrosting |

| SC | when unit is self-cleaning |

| FP | when freeze protection is turned on |

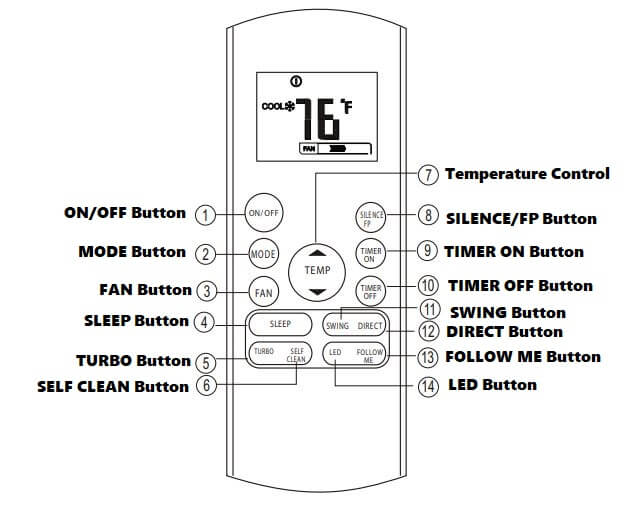

Remote Control Buttons Meaning

Troubleshooting

The following problems are not a malfunction and in most situations will not require repairs.

1. Unit does not turn on when pressing ON/OFF button: The unit has a 3-minute protection feature that prevents the unit from overloading. The unit cannot be restarted within three minutes of being turned off.

2.The unit changes from COOL/HEAT mode to FAN mode: The unit may change its setting to prevent frost from forming on the unit. Once the temperature increases, the unit will start operating in the previously selected mode again. The set temperature has been reached, at which point the unit turns off the compressor. The unit will continue operating when the temperature fluctuates again.

3.The indoor unit emits white mist: In humid regions, a large temperature difference between the room’s air and the conditioned air can cause white mist.

4.Both the indoor and outdoor units emit white mist: When the unit restarts in HEAT mode after defrosting, white mist may be emitted due to moisture generated from the defrosting process.

5.The outdoor unit makes noises: The unit will make different sounds based on its current operating mode.

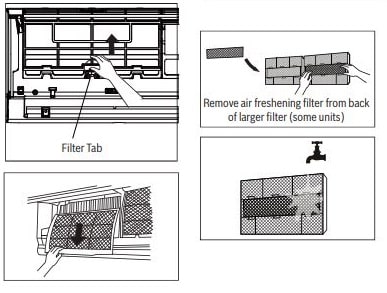

Cleaning Your Air Filter

A clogged air conditioner can reduce the cooling efficiency of your unit, and can also be bad for your health. Make sure to clean the filter once every two weeks.

- Lift the front panel of the indoor unit.

- First press the tab on the end of filter to loosen the buckle, lift it up, then pull it towards yourself.

- Now pull the filter out.

- If your filter has a small air freshening filter, unclip it from the larger filter. Clean this air freshening filter with a hand-held vacuum.

- Clean the large air filter with warm, soapy water. Ensure to use a mild detergent.

- Rinse the filter with fresh water, then shake off excess water.

- Dry it in a cool, dry place and refrain from exposing it to direct sunlight.

- When dry, re-clip the air freshening filter to the larger filter, then slide it back into the indoor unit.

- Close the front panel of the indoor unit.

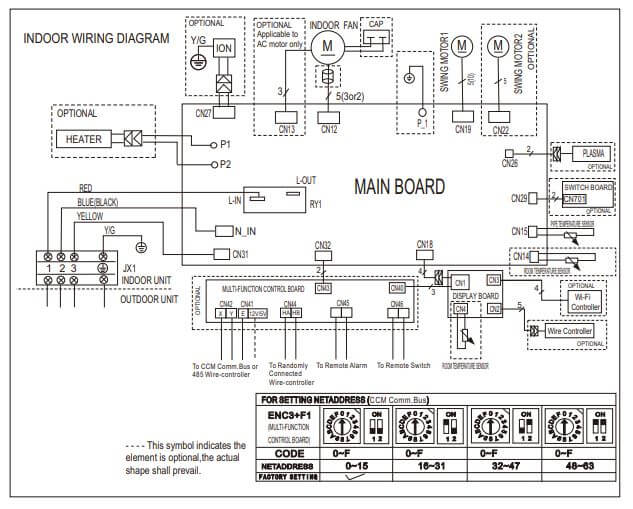

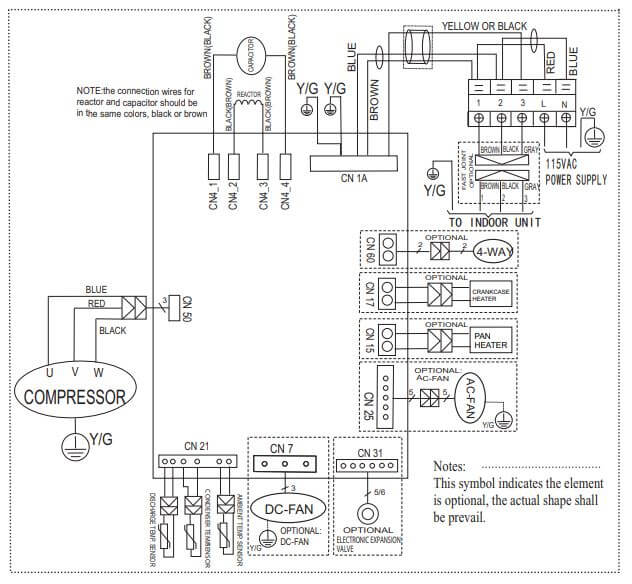

Wiring Diagrams

Manuals Pdf

Climate 5000 AA Series Split Type Ductless AC

Remote Controller for Split Type Ductless AC

- Unionaire Air Conditioner Error Codes - December 1, 2025

- Ameristar AC Error Codes and Troubleshooting - December 1, 2025

- Rheem Pool Heat Pump Error Codes - December 1, 2025

what does the code pc 04 mean on my Bosch climate 3000i? thanks in advance

what is the repair for e1 code.

thank you