Koppel is a Philippine-based company that started back in 1904 as a distributor of railway equipment. They commonly dealt with sugarcane cars, cargo cars, bulk carriers, and tankers for the Philippine National Railways. It was not until 1923 when the company joined hands with American Conglomerate that they started manufacturing and distributing American standard air conditioners.

However, it was not until 1957 that the company started to manufacture and market split and packaged air conditioning equipment. Making their move in the golden era they easily became a leader in the industry. In the years to come, the company went through a great deal, but Koppel managed to keep its focus on commercial and residential air conditioning systems.

Koppel might be a high-ranking company, but from time to time customers have complained about system errors. Fortunately, most of these errors can be fixed on your own. To help you out we have listed down some of the most common error codes for Koppel Air Conditioners. Start by noting down the error code, and match it using the list below. Once you have the error code you can easily work your way to the fix. Knowing what exactly the issue is, you are more likely to save time and money when looking for a quick and affordable fix.

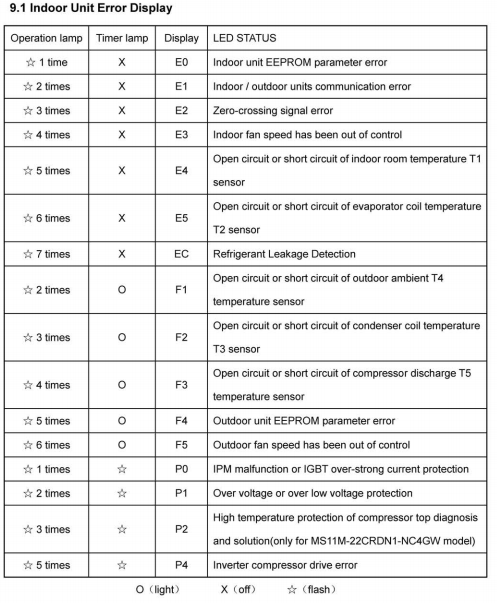

Codes List

E0: Indoor unit EEPROM parameter error

E1: Indoor / outdoor units communication error

E2: Zero-crossing signal error

E3: Indoor fan speed has been out of control

E4: Open circuit or short circuit of indoor room temperature T1

E5: Open circuit or short circuit of evaporator coil temperature T2 sensor

E6: Malfunction of indoor fan motor

EC: Refrigerant Leakage Detection

F1: Open circuit or short circuit of outdoor ambient T4 temperature sensor

F2: Open circuit or short circuit of condenser coil temperature T3 sensor

F3: Open circuit or short circuit of compressor discharge T5 temperature sensor

F4: Outdoor unit EEPROM parameter error

F5: Outdoor fan speed has been out of control

P0: IPM malfuntion of IGBT over-strong current protection

P1: Over voltage or over low voltage protection

P2: High temperature protection of compressor top diagnosis and solution

P4: Inverter compressor drive sensor

Troubleshooting

| Malfunction | Possible Causes |

|---|---|

| Strange odour | Air filter dirty |

| Noise of running water | Back flow of liquid in the refrigerant circulation |

| A fine mist comes from the air outlet | This occurs when the air in the room becomes very cold, for example in the COOLING or DEHUMIDIFYING/DRY modes |

| A strange noise can be heard | This noise is made by the expansion or contraction of the front panel due to variations in temperature and does not indicate a problem. |

| The display is off | Active LED function |

| The air conditioner cannot be started for operation after it is turned off | Start the operation after 3 minutes. This is to protect the air conditioner. The microchip protection device for 3 minutes' delay performs its function. When the machine is powered for the first time. this function does not work |

| Frog is blown out during the cooling operation | When the indoor temperature and humidity is high, such phenomena might occur. When the indoor temperature and humidity drops, the frog will disappear |

| There is odd smell of the delivered air | It might be the smell of cigarette smoke or other things inside the air conditioner |

| There is "squeezing" sound | It might be caused by the cycling of the refrigerant inside the air conditioner |

| There is "patting" sound | It might be caused by the heat expansion of contraction of the plastic parts |

| There is moisture at the air outlet grids | If the air conditioner operates in high humidity for long time, moisture may be condensed at the grids and become water drops |

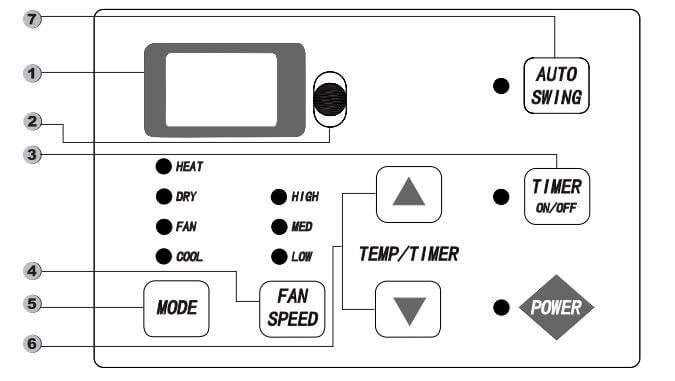

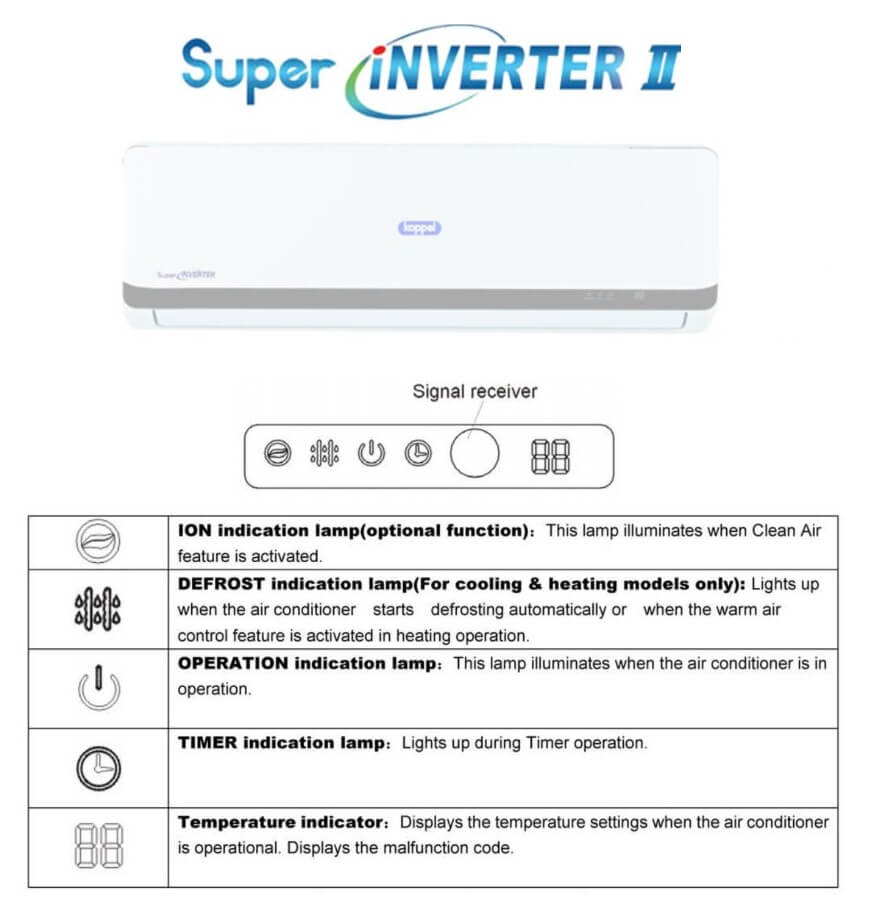

- Digital Displayer: in usual operation, in fan mode, ıt indicates room temperature; in cool or dry mode, ıt indicates setting temperature; in timer operation, when pressing the timer button, it indicates timer time, if the time has not been be adjusted after 5 seconds, it indicates temperature again; lf room temp sensor failure, ıt indicates temperature at 25‘c (77°f).

- Remote Controller Signal Receiver

- Timer Button: if unit is running, press this button will enter switch-off mode; if unit is off (in standby mode), press this button will enter switch-on mode.

- Speed Button: press this button to set air rate you want: high, med, low.

- Mode Button: press this button,it advances the operation mode as follows: cool -dry-fan(heat for cooling and heating model) – auto

- Temp-timer Button: in usual, press this button to adjust setting temperature within a range of 16‘c(61°f) to 32’s (90“f).

- Swing Button: pressing this button will adjust the air swinging direction or the air delivery in fixed direction.

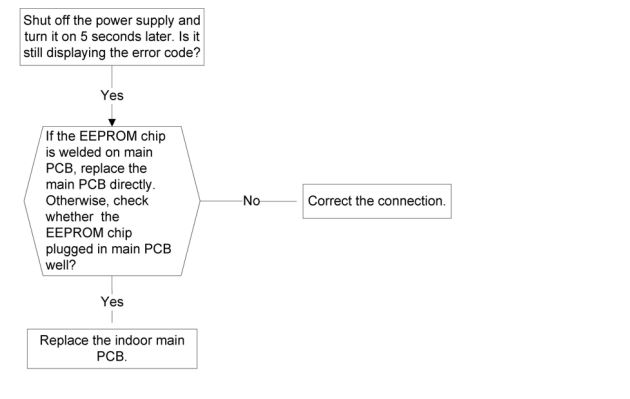

EEPROM parameter error diagnosis and solution E0/F4:

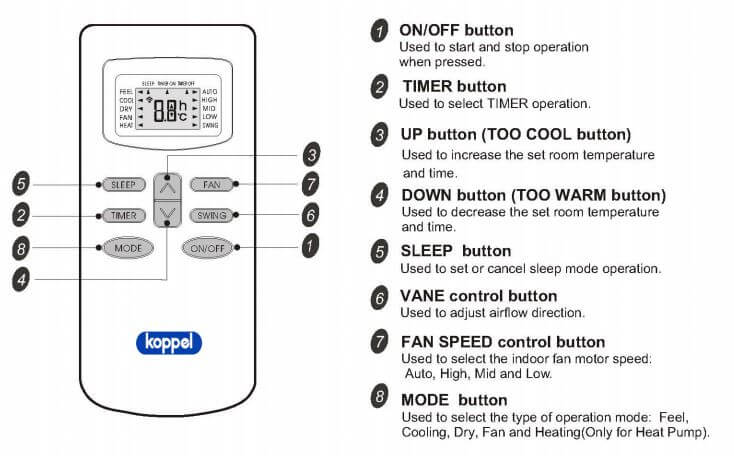

Remote Control

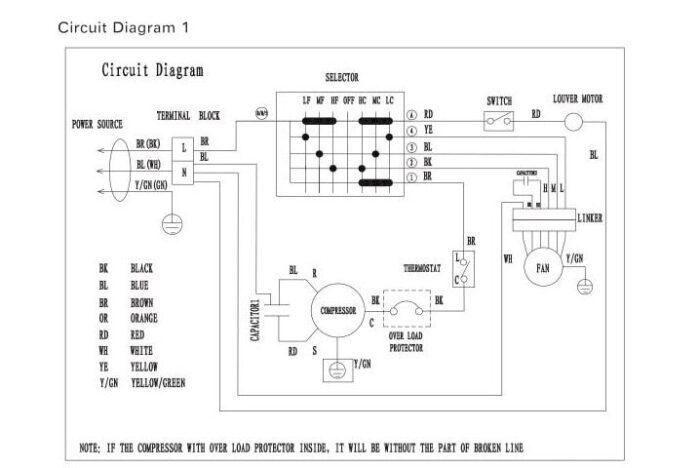

Wiring Diagram

Manuals PDF

- Unionaire Air Conditioner Error Codes - December 1, 2025

- Ameristar AC Error Codes and Troubleshooting - December 1, 2025

- Rheem Pool Heat Pump Error Codes - December 1, 2025

how to fix e1 and f4 error code?

good day! what is possible cause if the system always E,C.P6?P4? can u pls rply my message!the unit is vrf thanks god bless…

p4 and p6 is almost same error you should be check first power supply and then check the ipm board using tester by continuity,,

anu p po possible trouble error code kahit pagpalitin n po yung 3 wires . ganun pa din po tnx po .

how to fix when P1 error is displayed on my koppel AC? thanks!

Can you help me what is the parts problem if p1 indecate in ceiling inverter koppel,pls reply thank you.