Trane Technologies Inc. is a heating, ventilating, and air conditioning designer, manufacturer, and seller. A subsidiary of Ingersoll Rand Inc. the company is based in Swords, Dublin, and has managed to build a wide network around the world. With 104 manufacturing locations in 28 countries, the company is setting the world with one HVAC system at a time.

What started as a plumbing business, soon became manufacturing for heating products. Putting them in the direction of a cooling system, and lead to the first air conditioner production in 1931. After purchasing General Electronics they built on their findings and created systems that blew everyone away. Adding top-of-the-line requirements and technology to every new model they released, the company soon made a comfortable space at the top of the food chain.

Trane air conditioners are still considered to be the best out there, but there are times you will find an issue here or there. Some of the most common ones come forward as error codes. Start by noting down the error code, and match it using the list below. Once you have the error code you can easily work your way to the fix. To help you out we have listed down some of the most common error codes for Trane AC.

Split System Codes

When malfunction or protection occurs in the air conditioner, corresponding code will be displayed on the screen of the indoor unit and the indicator of outdoor unit will blink accordingly as well. When protection or malfunction is eliminated, display will be back to normal.

9, 12 MBH – 60 and 50 Hz ( No LED light on outdoor PCB)

| Error Code | Problem |

|---|---|

| EE | Storage slug |

| E1 | Indoor PCB malfunction |

| E2 | Anti-freezing protection |

| H4 | Overload system |

| H6 | No motor of indoor unit feedback |

| F2 | Indoor pipe temperature sensor malfunction |

| F1 | Internal ambient temperature sensor malfunction |

| UF | Zero passage abnormal |

| H3 | Overload of compressor |

| Lc | Startup failure |

| UH | No motor of outdoor unit feedback |

| E5 | Overcurrent protection |

| U7 | 4-way valve conversion abnormal |

| U1 | Phase current detection malfuntion of compressor |

12, 24 MBH – 60 and 50 Hz

| Error Code | Problem |

|---|---|

| E1 | System high pressure protection |

| E2 | Anti-freezing protection |

| E4 | Compressor air exhaust high temp. protection |

| E5 | AC overload protection |

| E6 | Indoor and outdoor units commication malfunction |

| E8 | Anti-high temp. protection |

| H6 | Indoor unit motor no feedback |

| C5 | Jump wire cap malfunction protection |

| F1 | Indoor ambient sensor open circuit, short circuit |

| F2 | Indoor evaporator sensor circuit open, short circuit |

| F3 | Outdoor ambient sensor circuit open, circuit short |

| F4 | Outdoor condensor sensor oepn circuit, short circuit |

| F5 | Outdoor air exhaust sensor open circuit, short circuit |

| F6 | Overload limit/descending frequency |

| F8 | Over current need frewuency descending |

| F9 | Air exhaust over high need frequency descending |

| PH | DC generatrix voltage |

| U3 | DC Bus voltage dips |

| PL | Low DC Bus voltage protection |

| EU | IPM temp. is too high limit/decrease frequency |

| U7 | Four-way valve abnormal |

| U9 | Outdoor unit zero-cross detecting error |

| FH | Anti-freezing limit/decrease frequency |

Error Messages and Actions

| Error Messages | Actions |

|---|---|

| 0x01 | EEPROM ERROR. ERROR 01 EEPROM communication error contact service technician. Unit stops working. Action to be taken by user: Contact service technician. |

| 0x02 | COMPRESSOR FAILURE ERROR OR Refrigerant Leakage Error. Error 02 Compressor failure or refrigerant leakage contact service technician. Unit stops working. Action to be taken by user: Contact service technician. |

| 0x03 | FILTER CHOKE ERROR. Error 03 Filter choke error -Clean the filter. Unit operates as per user settings. Action to be taken by user: Clean filters. |

| 0x04 | Indoor Temp Sensor Error (Room). Error 04 Room Temp Sensor Failure Contact Service Technician. Cool Mode Or Dry Mode: Unit Operate With Compressor Off Fan Mode: Operates As Per User Setting. |

| 0x05 | Outdoor Temp Sensor Error. Error 05 Outdoor Temp Sensor Failure Contact Service Technician. Operates Indoor Unit And Outdoor Unit As Per User Setting. If Trane Mode Is Activated Unit Should Operate At Set Point 24 °C. |

| 0x06 | Indoor Coil Sensor Error. Error 06 Indoor Temp Sensor Failure Contact Service Technician. Cool Mode Or Dry Mode: Unit Operate With Compressor Off Fan Mode: Operates As Per User Setting. |

| 0x08 | Communication Error. Error 08 Communication Error Contact Service Technician. Stop Indoor Unit And Outdoor Unit. |

| 0x09 | BATTERY LOW ERROR. Error 09 Low battery please change the battery. Operates indoor unit and outdoor unit as per user setting. Action to be taken by user: Change battery. |

| 0x0A | Input Power Error. Error 10 Idu Error - Input Power Problem. Unit Stops Working. Action To Be Taken By User: Check The Power Cord / Contact Service Technician |

| 0x0B | Fan Failure Error. Error 11 IDU Error - Fan Failure. Unit Stops Working. |

Mini / Multi-Split Wired Controller

| Fault Codes | Meaning |

|---|---|

| F1 | Return air temperature sensor open/short circuited |

| F2 | Evaporator temperature sensor open/short circuited |

| b5 | Indoor unit liquid valve temperature sensor open/ short circuited |

| b7 | Indoor gas valve temperature sensor open/short circuited |

| P7 | IPM temperature sensor open/short circuited |

| F3 | Outdoor ambient temperature sensor open/short circuited |

| F4 | Outdoor unit condenser mid-tube temperature sensor open/short circuited |

| F5 | Discharge temperature sensor open/short circuited |

| E6 | Indoor and outdoor communication error |

| PL | DC bus under-voltage protection |

| PH | DC bus over-voltage protection |

| U1 | Compressor phase current sensing circuit error |

| HE | Compressor demagnetization protection |

| Hc | PFC protection |

| P8 | IPM Temperature Protection |

| L9 | Over-power protection |

| F0 | System charge shortage or blockage protection |

| PU | Capacitor charging error |

| E1 | High pressure protection |

| E3 | Low pressure protection |

| LE | Compressor stalling |

| LF | Over-speeding |

| PF | Drive board temperature sensor error |

| P9 | AC contactor protection |

| PE | Temperature drift protection |

| Pd | Sensor connection protection |

| U3 | Sensor connection protection |

| L3 | Outdoor fan 1 error protection |

| LA | Outdoor fan 2 error protection |

| P6 | Drive board communication error |

| H3 | Compressor overheating protection |

| LP | Indoor and outdoor units unmatched |

| dn | Communication line mis-connected or expansion valve error |

| E7 | Running mode conflict |

| Fo | Pump-down |

| H1 | Forced defrosting |

| Lc | Compressor startup failure |

| E4 | High discharge temperature protection |

| E8 | Overload protection |

| E5 | Whole unit over-current protection |

| P5 | Over phase current protection |

| H7 | Compressor desynchronizing |

| H5 | IPM Current protection |

| Ld | Compressor phase loss/reversal protection |

| F8 | Frequency restricted/reduced with whole unit current protection |

| En | Frequency restricted/reduced with IPM current protection |

| F9 | Frequency restricted/reduced with high discharge temperature |

| FH | Frequency restricted/reduced with anti-freezing protection |

| F6 | Frequency restricted/reduced with overload protection |

| EU | Frequency restricted/reduced with IPM temperature protection |

| E9 | Indoor unit full water error |

| E2 | Anti-freezing protection |

| PP | AC input voltage abnormal |

| U5 | Whole unit current sensing circuit error |

| U7 | 4-way valve reversing error |

| H6 | Motor stalling |

| U8 | PG motor zero-crossing protection |

Mini TVR 5G Codes

Malfunction Code Of Outdoor Unit (12/14/16kw):

Display Function Instruction:

- When stand by, LED displaying the amount of indoor units online which communicate with outdoor units.

- When operation, LED displaying frequency value of compressor.

- When defrost, LED displaying “dF”.

| Display | Solution |

|---|---|

| H0 | M_Home unmatching |

| E0 | EEPROM Fault |

| E2 | Communication fault of the outdoor chip and the indoor chip |

| E3 | Communication error between Main board and IR341 |

| E4 | Outdoor unit sensor fault |

| E5 | Voltage protection fault |

| E6 | Direct-current fan fault |

| E7 | Heating fan fault in the area A lasts for 5 minutes |

| E8 | There are two times E6 fault in 10 minutes (recovery will be after power off) |

| P0 | The cooling fin high temperature protection |

| P1 | High pressure protection |

| P2 | Low pressure protection |

| P3 | Compressor current protection |

| P4 | Discharge temperature protection |

| P5 | Outdoor condenser high temperature protection |

| P6 | IPM modules protection |

| P7 | Evaporator high temperature protection |

| P8 | Typhoon protection |

Ceiling-Cassette Codes

| Error code | Explanation |

|---|---|

| 416 | Compressor down due to protection control of the discharge temperature sensor |

| 450 | Error due to condenser temperature sensor when in cooling mode |

| 451 | Error of the low pressure switch (Protection control) |

| 425 | Reverse phase error (Protection control) |

| 551 | In removing frost |

| 221 | Error of outdoor temperature sensor (Open/Short) |

| 237 | Error of condenser temperature sensor (Open/Short) |

| 201 | System down caused by communication error after completion of tracking Mismatching of indoor unit quantity setting error after completion of tracking 5 times |

| 251 | Error of discharge temperature sensor (Open/Short) |

| 121 | Error of temperature sensor in the indoor unit (Open/Short) |

| 122 | Error of the heat exchanger sensor in the indoor unit (Open/Short) |

| 419 | Error of electronic expansion valve open in the outdoor unit (when it is detected more than once) |

| 422 | Error of electronic expansion valve close in the outdoor unit (when it is detected more than once) |

| 601 | Error of communication between the indoor unit and the wired remote controller |

| 602 | Master wired remote controller / slave wired remote controller |

| 606 | Polarity error (F1/F2, F3/F4 switched) |

| EA | Error of setting option for wired remote controller COM2 |

Troubleshooting

Before requesting service, perform following checks. If the trouble has not been corrected, please contact a local dealer or the nearest customer service centre. Be sure to inform them of the details of malfunctions and unit model number. Do not attempt to repair the unit yourself. Always consult an authorized service provider.

| Symptom | Remedy |

|---|---|

| Indoor unit does not give cool air immediately when unit starts. | Compressor restarts after approximately three minutes to protect itself. On compressor restarting units starts to give cool air again. |

| Unusual odor blowing from outlet when unit is started. | Open the door or window for 2 minutes and run the AC in Fan mode to allow fresh air inside the room. This helps to remove odors from the room. |

| Sound of water flow during operation. | This is caused by refrigerant flowing inside the unit. |

| Formation of mist while cooling. | Room air is cooled quickly by cold air flow which looks like fog. |

| Creaking noise during start or stop. | Deformation of plastic because of temperature change. |

| Unit does not operate. | Check electrical system connections, cords and fuses. Check if power supply is within 10% of rated supply. |

| Decreased cooling efficiency. | Check ‘set temperature’. Check for obstructions in air inlet and outlet. Check air filters for dirt. Check indoor fan speed. Check any other openings in the room. |

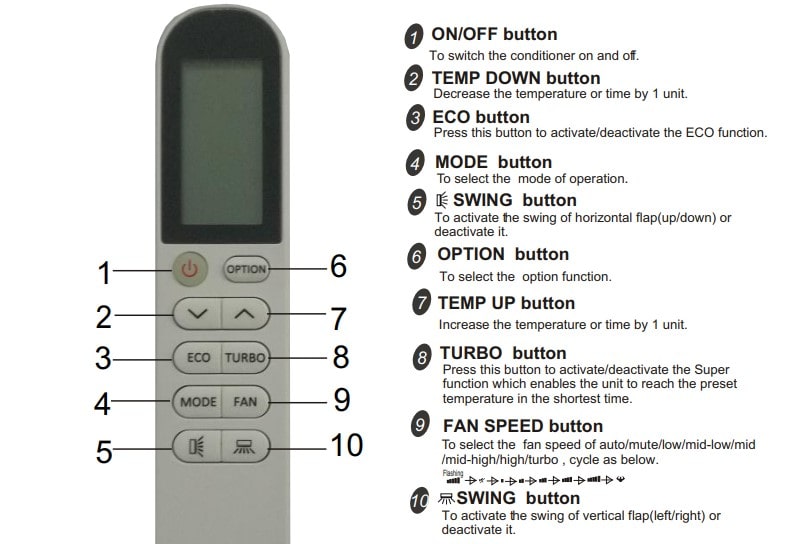

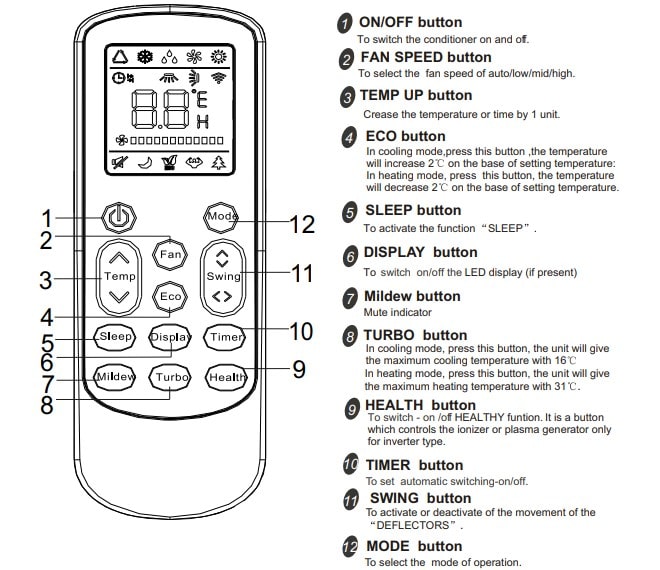

Remote Control

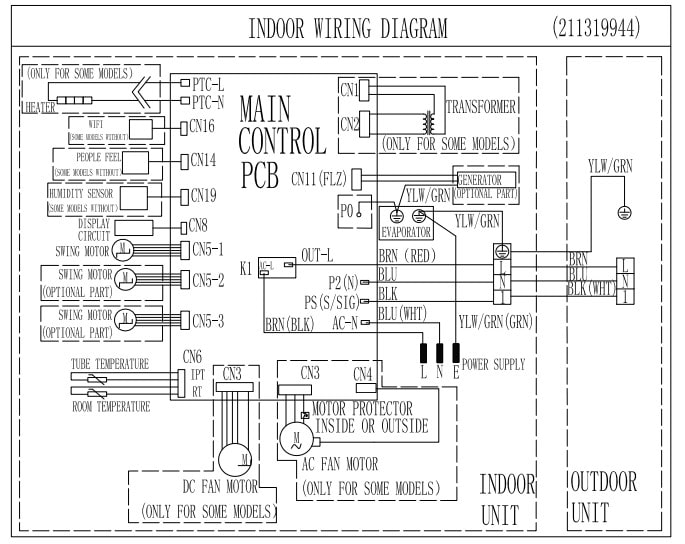

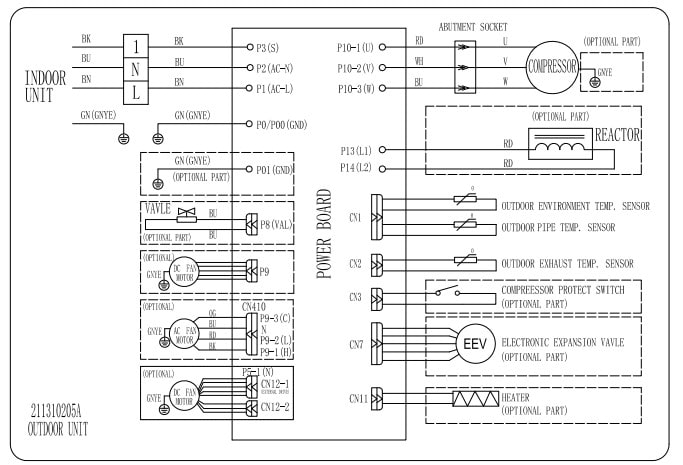

Wiring Diagram

Manual

- Unionaire Air Conditioner Error Codes - December 1, 2025

- Ameristar AC Error Codes and Troubleshooting - December 1, 2025

- Rheem Pool Heat Pump Error Codes - December 1, 2025

i have a probleme with my gainable, trane inveter 36000btu, code erreur P1, the compressor is runing for 2 mm and stoped.