Ruud air conditioner fault codes enhance user satisfaction by quickly detecting and resolving issues. Some error codes are listed below.

Comfort Alert Diagnosis Chart Single Phase Unit

Status LED: Green “POWER”

Status LED Description: Module has power

Status LED Troubleshooting Information: Supply voltage is present at module terminals

Status LED: Red “TRIP”

Status LED Description: Thermostat demand signal Y1 is present, but the compressor is not running

Status LED Troubleshooting Information:

- Compressor internal overload is open

- Broken wire or connector is not making contact

- Low pressure switch open, if present

- Compressor contactor has failed open

Status LED: Yellow “ALERT” Flash Code 1

Status LED Description: Long Run Time Compressor is running extremely long run cycles

Status LED Troubleshooting Information:

- Low refrigerant charge

- Evaporator blower is not running

- Evaporator coil is frozen

- Faulty TXV

- Condenser coil is dirty

- Liquid line restriction (filter drier blocked if present in system)

- Thermostat is malfunctioning

Status LED: Yellow “ALERT” Flash Code 2

Status LED Description: System Pressure Trip Discharge or suction pressure out of limits or compressor overloaded

Status LED Troubleshooting Information:

- Condenser coil poor air circulation (dirty, blocked, damaged)

- Condenser fan is not running

- Return air duct has substantial leakage

- If low pressure switch is present, check flash code (1) information

Status LED: Yellow “ALERT” Flash Code 3

Status LED Description: Short Cycling Compressor is running only briefly

Status LED Troubleshooting Information:

- High head pressure

- Thermostat demand signal is intermittent

- Time delay relay defective, if present

- Hot gas sensor defective, if present

Status LED: Yellow “ALERT” Flash Code 4

Status LED Description: Locked Rotor

Status LED Troubleshooting Information:

- Run capacitor has failed

- Low line voltage (contact utility if voltage at disconnect is low)

- Excessive liquid refrigerant in compressor

- Compressor bearings are seized

Status LED: Yellow “ALERT” Flash Code 5

Status LED Description: Open Circuit

Status LED Troubleshooting Information:

- Compressor contactor has failed open

- High pressure switch is open, If present

- Open circuit in compressor supply wiring or connections

- Unusually long compressor protector reset time due to extreme ambient temperature

- Compressor windings are damaged

Status LED: Yellow “ALERT” Flash Code 6

Status LED Description: Open Start Circuit Current only in run circuit

Status LED Troubleshooting Information:

- Run capacitor has failed

- Open circuit in compressor start wiring or connections

- Compressor start winding is damaged

Status LED: Yellow “ALERT” Flash Code 7

Status LED Description: Open Run Circuit Current only in start circuit

Status LED Troubleshooting Information:

- Open circuit in compressor run wiring or connections

- Compressor run winding is damaged

Status LED: Yellow “ALERT” Flash Code 8

Status LED Description: Welded Contactor Compressor always runs

Status LED Troubleshooting Information:

- Compressor contactor has failed closed

- Thermostat demand signal not connected to module

Status LED: Yellow “ALERT” Flash Code 9

Status LED Description: Low Voltage Control circuit < 17VAC

Status LED Troubleshooting Information:

- Control circuit transformer is overloaded

- Low line voltage (contact utility if voltage at disconnect is low)

Troubleshooting

Symptom: Unit will not run

Possible Cause:

- Power off or loose electrical connection

- Thermostat out of calibration-set too high

- Defective contactor

- Blown fuses

- Transformer defective

- High pressure control open (if provided)

- Interconnecting low voltage wiring damaged

Remedy:

- Check for correct voltage at compressor contactor in control box

- Reset

- Check for 24 volts at contactor coil – replace if contacts are open

- Replace fuses

- Check wiring-replace transformer

- Reset-also see high head pressure remedy-The high pressure control opens at 610 PSIG

- Replace thermostat wiring

Symptom: Condenser fan runs, compressor doesn’t

Possible Cause:

- Run or start capacitor defective (single phase only)

- Start relay defective (single phase only)

- Loose connection

- Compressor stuck, grounded or open motor winding. open internal overload

- Low voltage condition

- Low voltage condition

Remedy:

- Replace

- Replace

- Check for correct voltage at compressor – check & tighten all connections

- Wait at least 2 hours for overload to reset. If still open, replace the compressor.

- At compressor terminals, voltage must be within 10% of rating plate volts when unit is operating.

- Add start kit components.

Symptom: Insufficient cooling

Possible Cause:

- Improperly sized unit

- Improper airflow

- Incorrect refrigerant charge

- Air, non-condensibles or moisture in system

- Incorrect voltage

Remedy:

- Recalculate load

- Check – should be approximately 400 CFM per ton.

- Charge per procedure attached to unit service panel

- Recover refrigerant, evacuate & recharge, add filter drier

- At compressor terminals, voltage must be within 10% of rating plate volts when unit is operating.

Symptom: Compressor short cycles

Possible Cause:

- Incorrect voltage

- Defective overload protector

- Refrigerant undercharge

Remedy:

- At compressor terminals, voltage must be ± 10% of nameplate marking when unit is operating.

- Replace – check for correct voltage

- Add refrigerant

Symptom: Registers sweat

Possible Cause: Low evaporator airflow

Remedy: Increase speed of blower or reduce restriction – replace air filter

Symptom: High head-low vapor pressures

Possible Cause:

- Restriction in liquid line, expansion device or filter drier

- Flow check piston size too small

- Incorrect capillary tubes

- TXV does not open

Remedy:

- Remove or replace defective component

- Change to correct size piston

- Change coil assembly

- Replace TXV

Symptom: High head-high or normal vapor pressure – Cooling mode

Possible Cause:

- Dirty condenser coil

- Refrigerant overcharge

- Condenser fan not running

- Air or non-condensibles in system

Remedy:

- Clean coil

- Correct system charge

- Repair or replace

- Recover refrigerant, evacuate & recharge

Symptom: Low head-high vapor pressures

Possible Cause:

- Flow check piston size too large

- Defective Compressor valves

- Incorrect capillary tubes

Remedy:

- Change to correct size piston

- Replace compressor

- Replace coil assembly

Symptom: Low vapor – cool compressor – iced evaporator coil

Possible Cause:

- Low evaporator airflow

- Operating below 65°F outdoors

- Moisture in system

- TXV limiting refrigerant flow

Remedy:

- Increase speed of blower or reduce restriction – replace air filter

- Add Low Ambient Kit

- Recover refrigerant – evacuate & recharge – add filter drier

- Replace TXV

Symptom: High vapor pressure

Possible Cause:

- Excessive load

- Defective compressor

Remedy:

- Recheck load calculation

- Replace

Symptom: Fluctuating head & vapor pressures

Possible Cause:

- TXV hunting

- Air or non-condensibles in system

Remedy:

- Check TXV bulb clamp – check air distribution on coil – replace TXV

- Recover refrigerant, evacuate & recharge

Symptom: Gurgle or pulsing noise at expansion device or liquid line

Possible Cause: Air or non-condensibles in system

Remedy: Recover refrigerant, evacuate & recharge

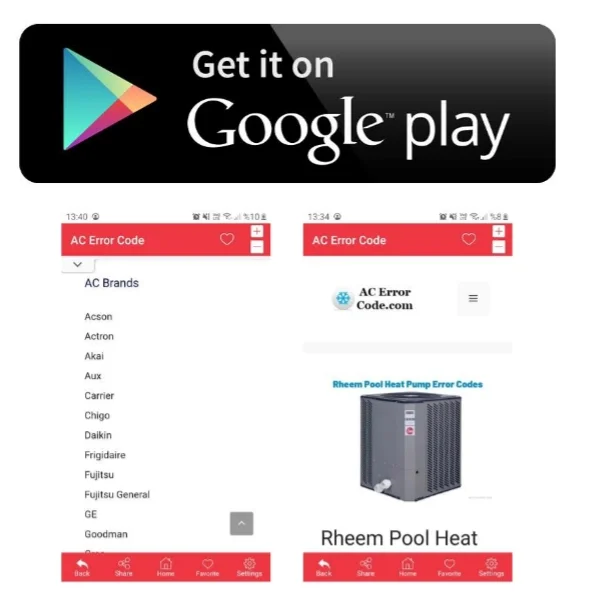

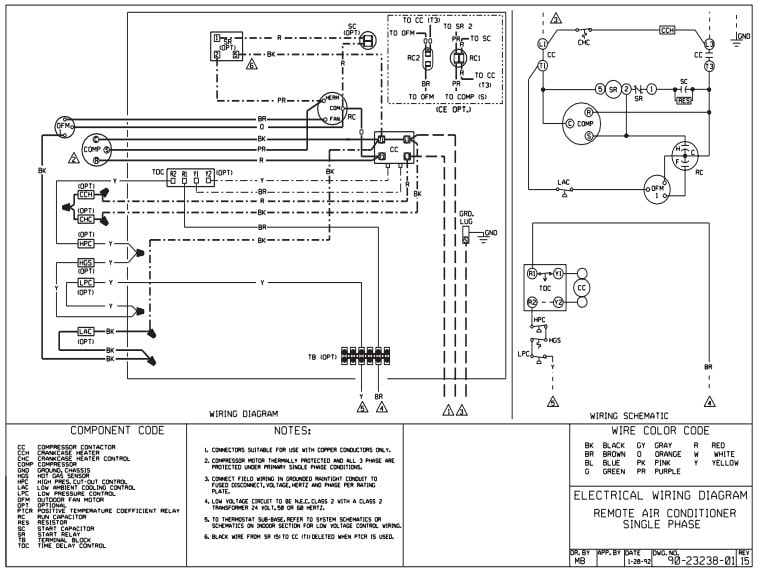

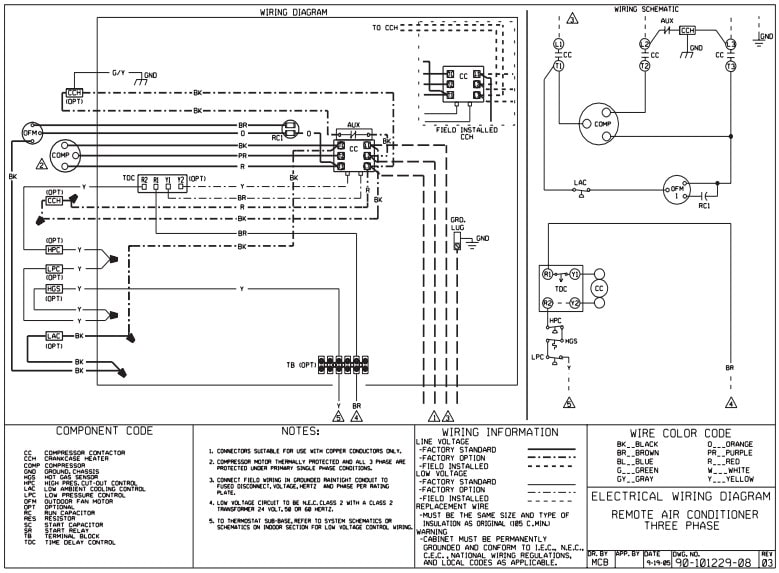

Wiring Diagram

Manual

Ruud Air Conditioners Manual PDF

- Fujitsu General VRF Error Codes With Solutions - January 15, 2025

- Unionaire Air Conditioner Error Codes and Information - January 15, 2025

- Teco AC Error Codes and Troubleshooting - January 15, 2025