If you’re experiencing issues with your Rheem AC, our guide on error codes is here to help. Our comprehensive resource covers everything from troubleshooting tips to fault code lists and PDF manuals to diagnose and solve problems with ease. Get your air conditioner back up and running in no time with our guide.

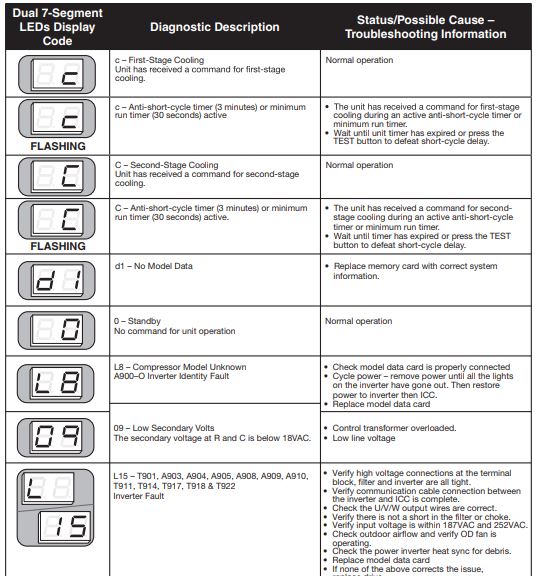

Codes Table

| Display Codes | Possible Cause |

|---|---|

| 0- Standby | No command for unit operation |

| c - First Stage Cooling | Unit has received a command for first stage cooling |

| c Flashing | Anti-short cycle timer (3 minutes) or Minimum run timer (30 seconds) active |

| C - Second Stage Cooling | Unit has received a command for second stage cooling |

| C Flashing | Anti-short cycle timer (3 minutes) or Minimum run timer (30 seconds) active |

| h - First Stage Heat Pump | Unit has received a command for first stage heat pump |

| h Flashing | Anti-short cycle timer (3 minutes) or Minimum run timer (30 seconds) action |

| H - Second Stage Heat Pum | Unit has received a command for second stage heat pump |

| H Flashing | Anti-short cycle timer (3 minutes) or Minimum run timer (30 seconds) active |

| d - Defrost Active | The unit is undergoing a defrost cycle |

| t - Test Mod | Test Mod |

| P - Protector Trip | A command for compressor operation is present but no current is measured to the compressor |

| 01 - Long Run Time (Compressor) | The compressor has continuously run for more than 18 hours in the cooling mode. |

| 02 - High Pressure | Compressor limit has opened four (4) times within a call for operation |

| 03 - Short Cycling | ICC detects the run time for the past four (4) compressor or cycles is less than three (3) minutes each |

| L4 - Locked Rotor | The ICC detects four (4) consecutive protector trips have occurred and the average run time for each trip is less than 15 seconds |

| 05 - Open circuit (Compressor Will not Run) | The ICC has had a protector trip for longer than 4 hours |

| 06 - Compressor Open Start Circuit | The ICC detects current in the Run circuit but not in the Start circuit of the compressor |

| L6 - Compressor Open Start Circuit | The ICC detects current in the Run circuit but not in the Start circuit of the compressor four (4) times in one compressor call |

| 07 - Compressor Open Run Circuit | The ICC detects current in the Start circuit but not in the Run circuit of the compressor |

| L7 - Compressor Open Run Circuit | The ICC detects current in the Start circuit but not in the Run circuit of the compressor four (4) times in one compressor call |

| 09 - Low Secondary Volts | The secondary voltage at R and C is below 18VAC |

| 21 - Low Pressure Control Open | The ICC detects the LPC is open. Note: The low pressure control is ignored for the first 90 seconds of compressor operation |

| L21 Flashing | Active Protection, Low Pressure Control Trip |

| 27 | Low Line Voltage or No Line Voltage Fault |

| 28 | High Line Voltage Fault |

| 29 | High Pressure Control Open. The ICC detects the HPC is open |

| L29 Flashing - Active Protection | High Pressure Control Trip |

| 30 - Fuse Open | The ICC detects the on—board fuse is open |

| 80 - Low Air Flow | The ICC detects that the indoor unit is not providing the minimum airflow requirements. |

| 83 - Condenser Coil Temperature Fault | The sensor detects an abnormally low or high coil temperature |

| 84 - Outdoor Ambient Temperature Fault | The sensor detects an abnormally low or high outdoor ambient temperature |

| 93 - Internal Control Fault | The control is not functioning properly. |

| d1 | N0 Shared Data |

| d3 - Airflow CFM Mismatch | The indoor air mover (air handler/furnace) cannot supply the required airflow for proper system operation |

| d4 - (Device) Memory Card Invalid for Device | The data in the memory card inserted into the control board does not match the data in the control. |

| d8 - Old Shared Data | System data is obsolete |

Diagnostic Codes

Descriptions of the ICC diagnostic codes are provided below: NOTE: Codes must be read from correct side to avoid an error in reading codes.

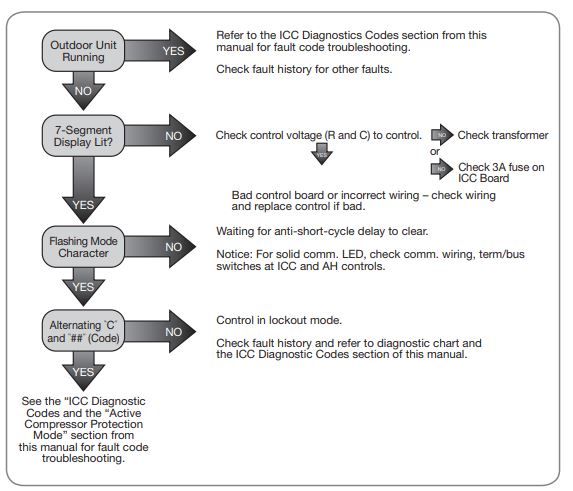

Electrical Checks Flowchart

Thermostat Call For Cooling, No Cooling

Troubleshooting

Disconnect all power to unit before servicing. Contactor may break only one side. Failure to shut off power can cause electrical shock resulting in personal injury or death.

SYMPTOM: Unit will not run

POSSIBLE CAUSE:

- Power off or loose electrical connection

- Thermostat out of calibration – set too high

- Defective control board

- Blown fuses/tripped breaker

- Transformer defective

- High-pressure control open/Low-pressure control open

- Miswiring of communications

REMEDY:

- Check for correct voltage at line voltage connections in condensing unit.

- Reset.

- Check control board diagnostic codes.

- Replace fuses/reset breaker.

- Check wiring. Replace transformer.

- Reset. Also see high head pressure remedy. The highpressure control opens at 610 PSIG.

- Check communication wiring

SYMPTOM: Outdoor fan runs, compressor doesn’t

POSSIBLE CAUSE:

- Run or start capacitor defective

- Contactor defective

- Loose connection

- Compressor stuck, grounded or open motor winding, open internal overload.

- Low-voltage condition

REMEDY:

- Replace.

- Replace.

- Check for correct voltage at compressor. Check and tighten all connections.

- Wait at least 3 hours for overload to reset. If still open, replace the compressor.

- Add start kit components.

SYMPTOM: Insufficient cooling

POSSIBLE CAUSE:

- Improperly sized unit

- Improper indoor airflow

- Incorrect refrigerant charge

- Air, noncondensibles, or moisture in system

- Bad ID TXV

REMEDY:

- Recalculate load.

- Check. Should be approximately 400 CFM per ton.

- Charge per procedure attached to unit service panel.

- Recover refrigerant. Evacuate and recharge. Add filter drier.

- Replace TXV

SYMPTOM: Compressor short cycles

POSSIBLE CAUSE:

- Incorrect voltage

- Defective overload protector

- Refrigerant undercharge

REMEDY:

- At compressor terminals, voltage must be ± 10% of nameplate marking when unit is operating.

- Replace. Check for correct voltage.

- Add refrigerant.

SYMPTOM: High head, low vapor pressures

POSSIBLE CAUSE:

- Restriction in liquid line, expansion device, or filter drier

- Bad TXV

REMEDY:

- Remove or replace defective component.

- Replace TXV

SYMPTOM: High head, high or normal vapor pressure – Cooling mode

POSSIBLE CAUSE:

- Dirty outdoor coil

- Refrigerant overcharge

- Outdoor fan not running

- Air or noncondensibles in system

REMEDY:

- Clean coil.

- Correct system charge.

- Repair or replace.

- Recover refrigerant. Evacuate and recharge

SYMPTOM: Low head, high vapor pressures

POSSIBLE CAUSE:

- Bad TXV

- Bad compressor

REMEDY:

- Replace TXV.

- Replace compressor

SYMPTOM: Low vapor, cool compressor, iced indoor coil

POSSIBLE CAUSE:

- Low indoor airflow

- Operating below 65°F outdoors

- Moisture in system

- Closed ID circuit

REMEDY:

- Increase speed of blower or reduce restriction. Replace air filter.

- Add Low Ambient Kit.

- Recover refrigerant. Evacuate and recharge. Add filter drier.

- Repair or replace ID coil

SYMPTOM: High vapor pressure

POSSIBLE CAUSE:

- Excessive load

- Defective compressor

REMEDY:

- Recheck load calculation.

- Replace.

SYMPTOM: Fluctuating head and vapor pressures

POSSIBLE CAUSE:

- TXV hunting

- Air or noncondensibles in system

REMEDY:

- Check TXV bulb clamp. Check air distribution on coil. Replace TXV.

- Recover refrigerant. Evacuate and recharge.

Manual Pdf

source: www.rheem.com

- Unionaire Air Conditioner Error Codes - December 1, 2025

- Ameristar AC Error Codes and Troubleshooting - December 1, 2025

- Rheem Pool Heat Pump Error Codes - December 1, 2025

Rheem 2.5ton, E7 error code?