Friedrich is a family-owned business that comes with a rich history based in the city of San Antonio. From the San Antonio Zoo, Buckhorn Saloon, and Friedrich Wilderness Park, to Friedrich air conditioning the company has shown innovation, philanthropy, and ingenuity at its best. Ed Friedrich founded the business back in 1883 when the company designed furniture using the horns of the longhorn cattle. However, that is not where the story ended, the family was full of innovative thinkers who were constantly working on tending to the market’s needs.

Such innovative thinking and smart working is what brought the company its fame and glory to a point where the company was regarded as one of the best in the world. Offering solutions to consumers the company still focuses on offering products that match the time and needs of its consumers. Regardless of how high a company is ranked, or how well the appliance is reviewed, you are at the risk of an error. An error is not here to tell you it’s time to switch out your appliance, it’s a direct signal from the device – one that tells the owner something is wrong with the system that needs to be fixed. So rather than ignoring the error codes, your appliance is showing it’s time to note down the Friedrich Air conditioner error code and get to the bottom of the problem. To help you out we have listed down the most common error codes of Friedrich Air conditioners.

PTAC Codes

The Friedrich Smart Center continuously monitors the PTAC unit operation and will store service codes if certain conditions are witnessed. In some cases the unit may take action and shut the unit off until conditions are corrected.

PTAC – PD Series

Packaged Terminal Air Conditioners

Packaged Terminal Heat Pumps

| Error Codes | Problem |

|---|---|

| E1 | High pressure protection of system |

| E2 | Antifreezing protection |

| F0 | In defect of refrigerant |

| E4 | High discharge temperature protection of compressor |

| E5 | Overcurrent protection |

| E6 | Communication Malfunction |

| E8 | High temperature resistant protection |

| EE | EEPROM malfunction |

| EU | Limit/decrease frequency due to high temperature of module |

| C5 | Malfunction protection of jumper cap |

| Fo | Gathering refrigerant |

| F1 | Indoor ambient temperature sensor is open/short circuite |

| F2 | Indoor evaporator temperature sensor is open/short circuited |

| F3 | Outdoor ambient temperature sensor is open/short circuited |

| F4 | Outdoor condenser temperature sensor is open/short circuited |

| F5 | Outdoor discharge temperature sensor is open/short circuited |

| F6 | Limit/ decrease frequency due to overload |

| F8 | Decrease frequency due to overcurrent |

| F9 | Decrease frequency due to high air discharge |

| FH | Limit/ decrease frequency due to antifreezing |

| PH | Voltage for DC bus-bar is too high |

| PL | Voltage of DC bus-bar is too low |

| P0 | Compressor Min frequence in test stat |

| P1 | Compressor rated frequence in test state |

| P2 | Compressor maximum frequence in test state |

| P3 | Compressor intermediate frequence in test stat |

| P5 | Overcurrent protection of phase current for compressor |

| PU | Charging malfunction of capacitor |

| P7 | Malfunction of module temperature sensor circuit |

| P8 | Module high temperature protection |

| H0 | Decrease frequency due to high temperature resistant during heating operation |

| H1 | Defrosting |

| H2 | Static dedusting protection |

| H3 | Overload protection for compressor |

| H4 | System is abnormal |

| H5 | IPM protection |

| H6 | Internal motor (fan motor) do not operate |

| H7 | Desynchronizing of compressor |

| HC | PFC protection |

| L3 | Outdoor DC fan motor malfunction |

| L9 | Power protection |

| LP | Indoor unit and outdoor unit doesn't match |

| LC | Failure startup |

| U1 | Malfunction of phase current detection circuit for compressor |

| U3 | Malfunction of voltage dropping for DC bus-bar |

| U5 | Malfunction of complete units current detection |

| U7 | The four-way valve is abnormal |

| U9 | Zerocrossing malfunction of outdoor unit |

| A2 | There is an issue with the power supply to the heater. |

Window/Room AC Codes

| Fault Codes | Solution |

|---|---|

| CH01 | Indoor Air Sensor Error. Indoor air sensor open or short. |

| CH09 | EEPROM CheckSum Error. EEPROM reading date error. |

| CH34 | High Pressure Error. As high pressure,comp off over 10 times in 1 hour. |

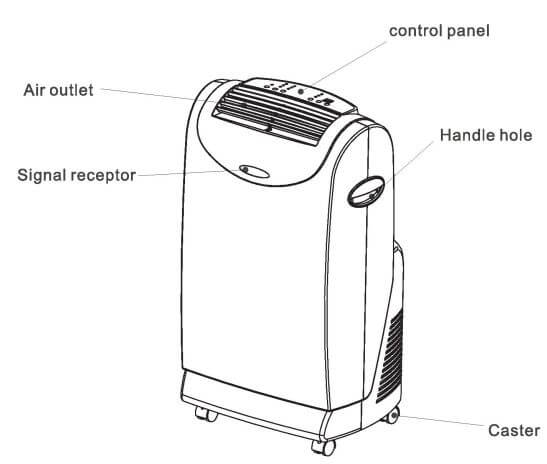

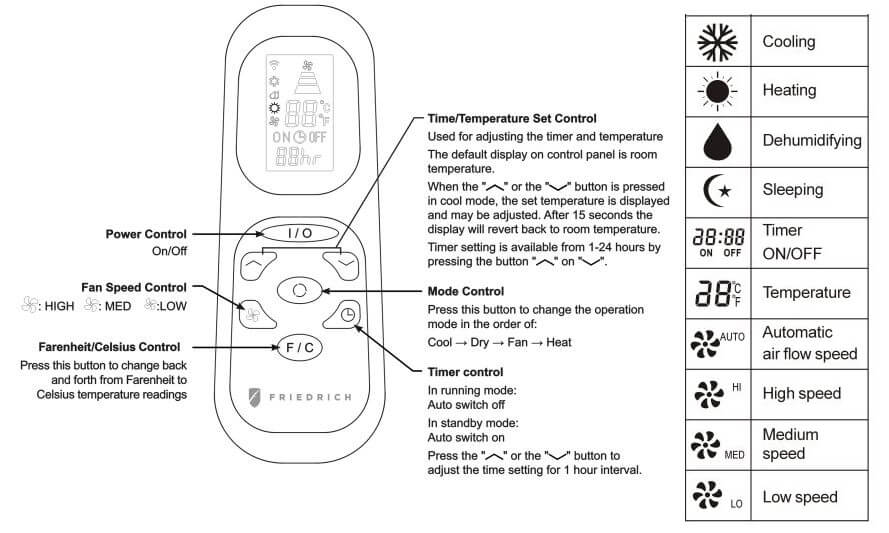

Portable Codes

| Error Codes | Cause |

|---|---|

| E1 | Electrical short on both temperature sensor and PCB. |

| E2 | Electrical short of temperature sensor copper tube and PCB wiring. |

| E4 | Indicates water tank full or poor contact of signal plug. User needs to pull out the rubber stopper which is located at the bottom of the unit, to drain the water away. Check that the plug has been wired correctly. |

Portable AC Troubleshooting

| Problem | Possible Cause |

|---|---|

| The airconditioner doesn't work | There is a power failure, Wait for the power return. |

| The plug is not connected. Connect the plug. | |

| The timer is unable to work. Provide repairment. | |

| The main switch has not been pressed. Press the main switch. | |

| The airconditioner works for short period only | The set temperature is too close to the room's temperature. Decrease the setting temperature. |

| There is something blocking the suction vent on the back of condenser. Remove any obstacles. | |

| The fan on the condenser is blocked. Provide repairment. | |

| The airconditioner switches are off constantly | Malfunction. Turn off the appliance remove the plug and contact the service center. |

| The appliance is very noisy and vibrates violently | The compressor blocking device has been loosen or the copper pipe is getting in touch with the body of the set. Provide repairment. |

| When LED of unit shows E1 | There might be a broken or short circuit on ambient temperature sensor. Please check if it is sensor's problem. If not, contact manufacturer for replacing the PCB. |

| When LED of unit shows E2 | There might be a broken or short circuit on brass temperature sensor (only applicable for cooI/heat unit). Please check if it is sensor's problem. If not, contact manufacturer for replacing the PCB. |

Digital Control Diagnostics and Test Mode

| Error Code | Possible Cause |

|---|---|

| 02 | An extreme low voltage condition exists <198V for 230V units and <239V for 265V units. Action Taken by Unit: Shut down unit. Display Error code and flash. Once voltage rises to normal level system power is restored. |

| 03 | Return air thermistor sensor open or short circuit. Action Taken by Unit: Set return air sensor = 75°F. Alternate flash set point and error code. Leave unit running. Possible Cause: Defective sensor. |

| 04 | Indoor coil thermistor sensor open Or short circuit. Action Taken by Unit: Set ID coil temp = 40°F. Alternate flash set point and error code. Leave unit running. Possible Cause: Defective sensor. |

| 05 | Outdoor coil thermistor sensor open Or short circuit. Action Taken by Unit: SetOD coil temp = 20°F. Alternate flash set point and error code. Automatically change over to Electric heat Mode only. Leave unit running. Possible Cause: Defective sensor. |

| 06 | If O.D. coil Temperature > 175 Deg F for 2 consecutive minutes. (Heat Pump models only). Action Taken by Unit: Alternate flash set point and error code. Shut unit down for 5 minutes, then try again 2 times, if fails the 3rd time, then shut down unit. |

| 07 | I.D coil temperature <30 Deg F for 2 consecutive minutes. Action Taken by Unit: Alternate flash set point and error code. Continue fan operation while the compressor is locked out until the indoor coil thermistor reaches 45° F, and then energize the compressor. However, compressor must still wait a lockout time of 180 to 240 seconds. |

| 08 | If unit cycles (Heat or Cool demand)> 9 times per hour. Action Taken by Unit: Alternate flash set point and error code. Keep unit running. |

| 09 | If unit cycles (Heat or Cool demand)< 3 times per hour. Action Taken by Unit: Alternate flash set point and error code. Keep unit running. |

| 10 | Room Freeze Protection triggered. Action Taken by Unit: Alternate flash set point and error code. Keep unit running. Possible Cause: Room temperature fell below 40°F. |

Heat Pump Codes

Error Code Mode is used to display all error codes stored since reset. It is a sub-mode of Test Mode.

| Error Codes | Problem |

|---|---|

| E1 | SHORT CYCLE SITUATION: Defined as a compressor that starts and stops more frequently than it should (more than 6 times per hour). |

| E2 | KEYBOARD STUCK ERROR: If any key button is stuck or pressed for 20 seconds or more, the unit considers it stuck. If a key is stuck it will be ignored until released. If the “Mode” key is stuck, the unit’s function will default to Cool mode. |

| E3 | FROST PROBE OPEN: Normal operation is allowed. Replace probe. |

| E4 | FROST PROBE SHORT: Normal operation is allowed. Replace probe. |

| E5 | INDOOR PROBE OPEN: Control assumes indoor ambient temperature is 90 degrees F and unit will operate. Replace probe. |

| E6 | INDOOR PROBE SHORT: Control assumes ambient temperature is 90 degrees F and unit will operate. Replace probe. |

| E1 | SHORT CYCLE SITUATION: Defined as a compressor that starts and stops more frequently than it should (more than 6 times per hour). |

| E2 | KEYBOARD STUCK ERROR: If any key button is stuck or pressed for 20 seconds or more, the unit considers it stuck. If a key is stuck it will be ignored until released. If the “Mode” key is stuck, the unit’s function will default to Cool mode. |

| E3 | AMBIENT (INDOOR) AIR PROBE OPEN OR SHORT: Control will assume ambient temperature is 90 degrees F when in Cool mode and 60 degrees F when in Heat mode. Unit will operate (see note below). |

| E4 | EVAPORATOR TEMPERATURE PROBE OPEN OR SHORT: Normal operation is allowed. Replace probe. |

| E5 | CONDENSER TEMPERATURE PROBE OPEN OR SHORT: Normal operation is allowed. Replace probe. |

| E7 | MOTOR OPERATION |

| E9 | HEAT PUMP FAILURE |

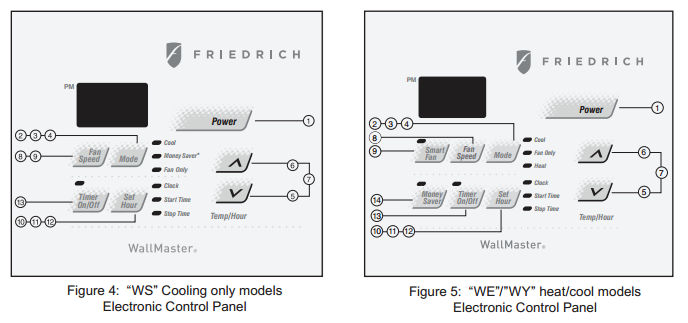

Unit must be in Test Mode to enter the Error Code function. Activating Error Code Mode: Press the TIMER On/Off” button (see figures 4 and 5). The LED for the TIMER On/ Off will flash 1 bps (beats per second) while Error Code Mode is active. Pressing the Temp/Hour button will display “00”. Consecutive presses will scroll through all error codes stored. Press the Temp/Hour button to see the reverse order of the error codes. When the end of the stored error codes is reached the temperature Set Point will appear. (Each error code is listed once).

Exiting Error Code Mode: press the Timer On/Off button.

Clearing Error Codes: Error codes are cleared from the memory by exiting from Error Code Mode.

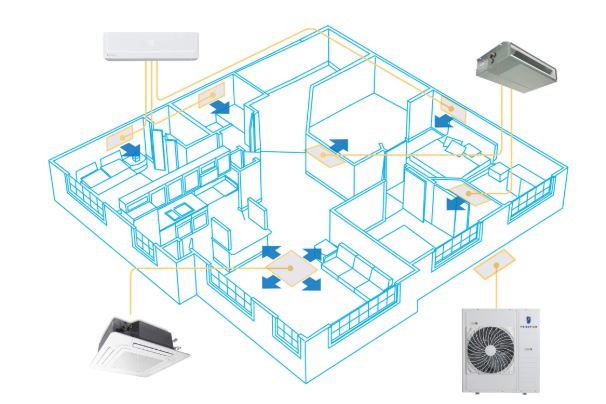

Multi Zone AC Codes

| Error Codes | Meaning |

|---|---|

| 00 | No Error |

| 01 | Indoor Room themistor error |

| 02 | Indoor in-piping sensor error |

| 03 | Remote controller error |

| 04 | Drain Pump error |

| 05 | Communcation error between in and out |

| 06 | Indoor Out-Piping sensor error |

| 07 | Differnt mode operation |

| 09 | EEPROM Check Sum Error |

| 10 | Indoor BLDC Fan Lock |

| 21 | DC Peak (IPM Fault) - Over Rated Current Off |

| 22 | CT 2(Max CT) 2times - Input Over Current Off |

| 23 | DC Link Low Volt. 2times - DC Link Volt is below 140Vdc Off |

| 24 | L_P/H_P Switch - Low/High Press Switch Open Off |

| 25 | Low Voltage/Over Voltage - Abnormal AC Volt Input Off |

| 26 | DC Compressor Position Error - Compressor Starting Fall Error Off |

| 27 | PSC/PFC Fault Error - Inverter PCB input current is over100A(peak) for 2us Off |

| 28 | DC Link High Volt - Off Off |

| 29 | COMP Over Current - Over Inverter Compressor Current Off |

| 32 | D-Pipe High (INV) - Off Off |

| 40 | CT Sensor (Open / Short) - CT Circuit Malfunction Off |

| 41 | INV. D-Pipe Th Error - Open/Short Off |

| 44 | Outdoor Air Th Error - Open/Short Off |

| 45 | Cond. Pipe Th Error - Open/Short Off |

| 46 | Suction Pipe Error - Open/Short Off |

| 51 | Capacity Over 5times - Over combination Off |

| 52 | Signal Error(DSP Board <-> Main Board) - Communication Poorly Off |

| 53 | Signal Error (Indoor <-> Outdoor) - Communication Poorly Off |

| 60 | EEPROM Check Sum Error - Check Sum Mismatching Off |

| 61 | Cond. Pipe Th High - Cond. Temp. High Off |

| 62 | Heatsink Th High -Heatsink Temp. High Off |

| 65 | Heatsink Th Error - Open/Short Off |

| 67 | Outdoor BLDC Fan Lock - Outdoor Fan is not operating Off |

| 73 | PFC Fault Error(S/W) - Over Current of Outdoor Unit PFC |

Alarm Status

| Error Codes | Problem |

|---|---|

| 1 | Maintenance ICON: Flash. Front Panel Button Stuck For More Than 20 Seconds Continue to monitor for "OPEN" (Unstuck) switch. Do not process switch input. ENSURE FRONT COVER DOES NOT DEPRESS BUTTONS |

| 2 | Maintenance ICON: Flash. Input Voltage Out of Specification (103 - 127 / 187 - 253) Stop.Open all relays until voltage is back within specs. Resume operation. |

| 3 | Maintenance ICON: Flash. Indoor Temperature Sensor is Open or Shorted Set temp to 75°F in COOLING or 68°F in HEATING. Unit continues to operate. |

| 4 | Maintenance ICON: Flash. Indoor Coil Temperature Sensor is Open or Shorted Control Board sets temp to 40°F. Override sensor. Unit Continues to operate. |

| 5 | Maintenance ICON: Flash. Outdoor Coil Temperature Sensor is Open or Shorted Sets temp to 20°F. Override sensor. Continue operation. Use Elec Heat if available for HEATING. If not available use HEAT PUMP if outdoor temp allows. |

| 6 | Maintenance ICON: Flash. Outdoor Coil > (grater than) 175 F. Shut down for 5 min. Resume operation for 3 min. Continues to monitor. If test fails 3 times, the severity is increased and the unit operation is locked out. |

| 7 | Maintenance ICON: Flash. Indoor Coil < (less than) 30 F for 2 consecutive minutes Turn compressor off. Run High Fan speed. When coil temp reachs 45°F resume operation after lockout time. |

| 8 | Maintenance ICON: Log Only. Unit Cycles > (grater than) 9 Times per hour. Continue operation. Continue to monitor. Take no action. Log Only. |

| 9 | Maintenance ICON: Log Only. Unit Cycles < (less than) 3 Times per Hour. Continue operation. Continue to monitor. Take no action. Log Only. |

| 10 | Maintenance ICON: Log Only. Room Freeze Protection Only used if Electric Heat is available. Run High Speed and Electric heat until room temp reaches 46°F. Display "FRZ" during operation. Logged Only. |

| 11 | Maintenance ICON: On. WallStat Problem or Connection Issue Severity 4 error is. Unit operates based on standard input mapping. Severity 2 error opens all relays. Unit will not operate. |

| 12 | Maintenance ICON: Flash. Discharge Air > (greater than) 185 F Shutdown heat pump and electric heater. Run high fan speed until temp is 100°F. Resume operation. Third occurance in 1 hour locks unit out. |

| 13 | Maintenance ICON: Flash. Prerssure Limit Switch Open If unit is cooling or heat pump on,shut down compressor. Run high fan until switch closes. Resume operation. Third occurance in 1 hour locks unit out. |

| 14 | Maintenance ICON: Flash. Discharge Air Temperature Sensor is Open or Shorted Override Sensor. Set temp to 75°F. Continue to monitor. Set error code 14 ON. |

| 15 | Maintenance ICON: Solid On. Heat Pump Error. If indoor coil temp < (Lesser than) ambient temp for 3 minutes. Unit uses electric heat to satisfy heating demand. |

| 16 | Maintenance ICON: Flash. Temperature Beyond Operating Limits. Ambient temp < (less than) 0°F and ambient temp > (greater than) 130°F. Set error code 16 ON. When cleared return unit to normal. |

| 17 | Maintenance ICON: Flash. Equipment Doesn't Meet Minimum Configuration. Must have compressor enabled and at least 2 fan speeds |

| 18 | Maintenance ICON: Flash. Special Test 1 Severity Level 1. Unit shuts down. Inputs via front panel or t-stat are ignored. Qualified Technical Service required URGENT. |

| 19 | Maintenance ICON: Flash. Special Test 2 Severity Level 2. Unit operates. Qualified Technical Service required. |

| 20 | Maintenance ICON: Solid On. Special Test 3 Severity Level 3 Error is Logged Only. Unit operates. Severity 3 keeps unit running. Attention is needed. |

| 21 | Maintenance ICON: OFF, Log Only. Special Test 4 Severity Level 4 Error is Logged Only. Unit operates. Severity 4 keeps unit running. |

| 22 | Maintenance ICON: OFF, Log Only. Outdoor Coil Temperature < 30 F for 2 consecutive Minutes. Unit will use electric heat to satisfy heating demands until temp > 45°F. Unit must be a Heat Pump. |

| 23 | Maintenance ICON: OFF, Log Only. Frost Protection (for Heat Pump Only Unit- YS10M10) Unit will run active defrost for a minimum of 6 minutes when Heat Pump run time is greater than 60 minutes and outdoor coil temp is 26 F or less. |

| 24 | Maintenance ICON: Flash, Outdoor Air Temperature Sensor is Open or Shorted. Continue with normal operation. Continue to monitor sensor. |

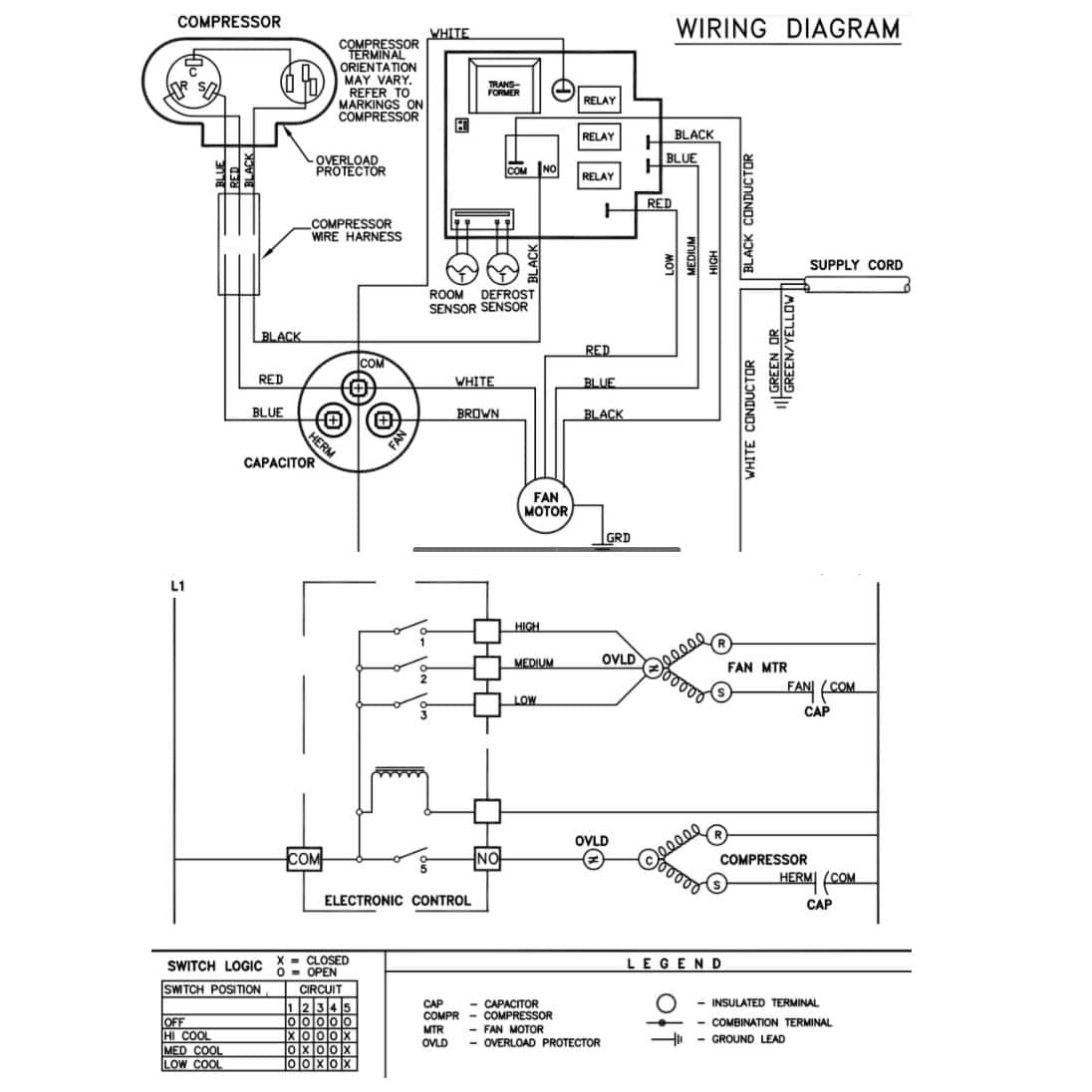

Wiring Diagram

Wallmaster Wiring Diagram Electronic Control Cool Only Models

Manuals Pdf

PTAC Installation And Operation

- Unionaire Air Conditioner Error Codes - December 1, 2025

- Ameristar AC Error Codes and Troubleshooting - December 1, 2025

- Rheem Pool Heat Pump Error Codes - December 1, 2025

I have code 05

I have a 15 or lS on both of ours

I have a error code ft what do I do

wrench symbol on wired thermostat and blinking 96 not cooling

I have an L3 code not working. how to fix it? thank you. (model mrm12y1j)

Hi, L3 error code; Outdoor DC fan motor malfunction.