If any error occurs in your air conditioner, indoor display shows error codes. Once you nail down the issue you can easily call in a professional, or fix the issue yourself. To help you out we have listed down the most common error codes of Lennox AC.

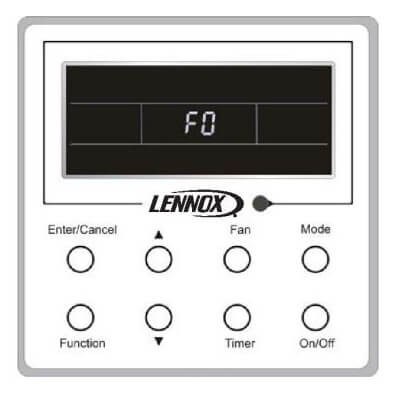

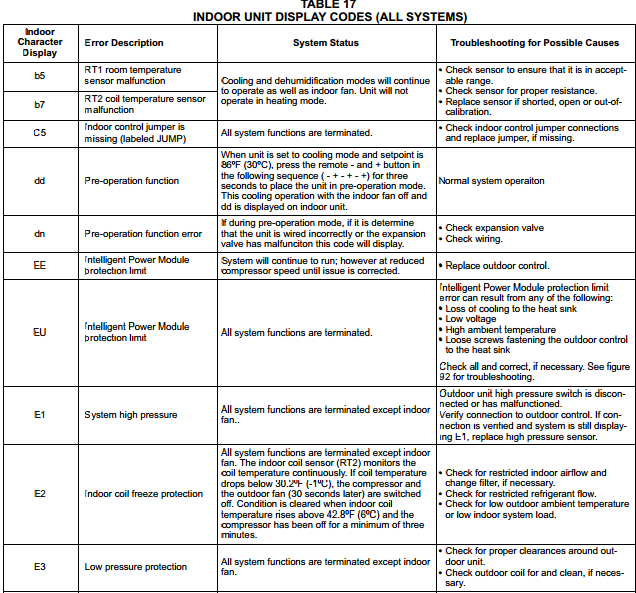

Indoor Unit Display Codes

- E0: EEPROM parameter error

- E1: Indoor/outdoor units communication protection

- E2: Zero-crossing signal error

- E3: Indoor fan speed out of control

- E5: Open or short circuit of outdoor temperature sensor or outdoor unit EEPROM parameter error

- E6: Open or short circuit of room or evaporator temperature sensor

- E7: Outdoor fan speed out of control

- P0: IBM malfunction or IGBT over strong current protection

- P1: Over voltage or too low voltage protection

- P2: Temperature protection of compressor top

- P4: Inverter compressor drive error

Split Type AC Codes

If there is an error occurring during the operation of the system, the error code will be displayed on the LCD, as show in Fig.5.1. If multi errors occur at the same time, their codes will be displayed circularly.

| Error Codes | Meaning |

|---|---|

| E1 | High pressure protection. |

| E2 | Anti-freezing protection. |

| E3 | Low pressure protection. |

| E4 | High discharge temperature protection. |

| E5 | Whole unit over-current protection. |

| E6 | Indoor and outdoor communication error. |

| E7 | Running mode conflict. |

| E8 | Overload protection. |

| E9 | Indoor unit full water error. |

| EN | Current protection. |

| EU | Frequency restricted/reduced with IPM temperature protection. |

| EL0C | Refrigerant leakage detection. |

| EH61 | Evaporator coil middle temperature sensor T2 is in open circuit or has short circuited. |

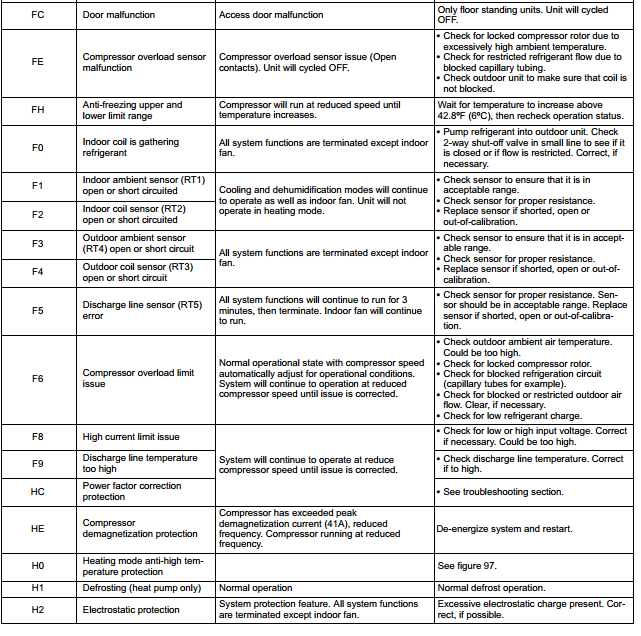

| F0 | System charge shortage or blockage protection. |

| F1 | Return air temperature sensor open/ short circuited. |

| F2 | Evaporator temperature sensor open/ short circuited. |

| F3 | Outdoor ambient temperature sensor open/ short circuited. |

| F4 | Outdoor unit condenser mid-tube temperature sensor open/short circuited. |

| F5 | Discharge temperature sensor open/ short circuited. |

| F6 | Frequency restricted/reduced with overload protection. |

| F8 | Frequency restricted/reduced with whole unit current protection. |

| F9 | Frequency restricted/reduced with high discharge temperature. |

| FH | Frequency restricted/reduced with antifreezing protection. |

| Fo | Pump-down. |

| H1 | Forced defrosting. |

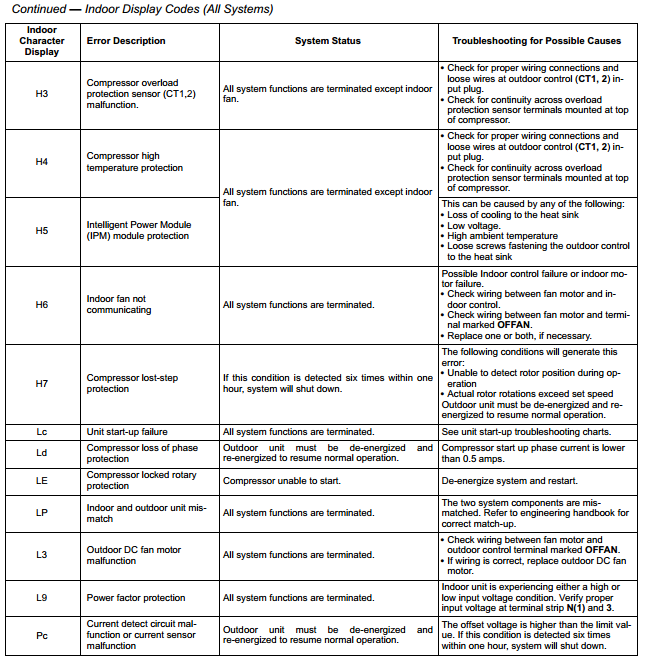

| H3 | Compressor overheating protection. |

| H5 | IPM Current protection. |

| H6 | Motor stalling. |

| H7 | Compressor desynchronizing. |

| HC | PFC protection. |

| HE | Compressor demagnetization protection. |

| P5 | Over phase current protection. |

| P6 | Drive board communication error. |

| P7 | IPM temperature sensor open/short circuited. |

| P8 | IPM Temperature Protection. |

| P9 | AC contactor protection. |

| PD | Sensor connection protection. |

| PE | Temperature drift protection. |

| PF | Drive board temperature sensor error. |

| PH | DC bus over-voltage protection. |

| PL | DC bus under-voltage protection. |

| PP | AC input voltage abnormal. |

| PU | Capacitor charging error. |

| PC00 | Inverter module IPM error. |

| PC01 | High or Low voltage protection. |

| PC02 | High temperature sensed at compressor top. |

| PC03 | Low or High pressure protection. |

| PC04 | Inverter compressor drive error. |

| PC08 | Current overload protection. |

| PC0L | Outdoor low ambient temperature protection. |

| U1 | Compressor phase current sensing circuit error. |

| U3 | DC bus voltage drop error. |

| U5 | Whole unit current sensing circuit error. |

| U7 | 4-way valve reversing error. |

| U8 | PG motor zero-crossing protection. |

| L3 | Outdoor fan 1 error protection. |

| L9 | Over-power protection. |

| LA | Outdoor fan 2 error protection. |

| LC | Compressor startup failure. |

| LD | Compressor phase loss/reversal protection. |

| LE | Compressor stalling. |

| LF | Over-speeding. |

| LP | Indoor and outdoor units unmatched. |

| B5 | Indoor unit liquid valve temperature sensor open/short circuited. |

| B7 | Indoor gas valve temperature sensor open/ short circuited. |

| C5 | Jumper error. |

| DN | Communication line misconnected or expansion valve error. |

| 105 | Device communication failure |

| 120 | Unresponsive device |

| 124 | Active subnet controller missing |

| 125 | Hardware failure |

| 126 | Internal control communication failure |

| 131 | Corrupted control parameters |

| 132 | Failed flash CRC check |

| 180 | Ambient sensor problem |

| 400 | Compressor internal overload trip |

| 401 | Long run time. Compressor is running extremely long run cycles |

| 402 | System pressure trip. |

| 403 | Short cycling. Compressor is running less than three minutes |

| 404 | Locked rotor. Compressor has a locked out due to run capacitor short, bearings are seized, excessive liquid refrigerant |

| 405 | Open circuit. |

| 406 | Open start circuit |

| 407 | Open run circuit |

| 408 | Welded contactor. Compressor always runs |

| 409 | Secondary low voltage. |

| 410 | Low pressure fault |

| 411 | Low pressure switch lockout |

| 412 | High pressure fault |

| 413 | High pressure switch lockout |

| 414 | Discharge line temperature fault |

| 415 | Discharge line temperature lockout |

| 417 | Discharge sensor fault |

| Ds11, Ds13, Ds14, Ds15 | OEM mode. Factory test mode |

Note: In event of any error, please turn off the unit and contact the professionally skilled personnel.

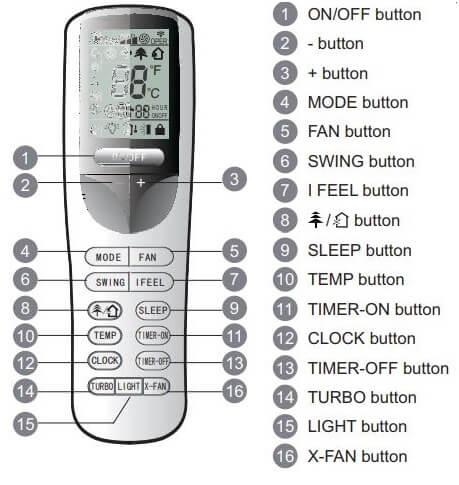

Remote Control Buttons Meaning

Mini Split Type Codes

Indoor and Outdoor Error Codes

Rooftop Codes

Climatic 50 Roof-Top, Aircoolair & Compactair Version 24

| Error Codes | Problem |

|---|---|

| 001 | Airflow |

| 004 | Filters, Clogged up |

| 005 | Filters, Missing |

| 006 | Recovery Module, Filters, Clogged up |

| 011 | Electric heating elements |

| 012 | High Temperature, Blowing |

| 013 | Low Temperature, Ambient |

| 022 | Low Temperature, Blowing |

| 023 | High Temperature, Ambient |

| 051 | Recovery Module, Motor failure |

| 052 | Recovery Module, Wheel failure |

| 081 | Temperature sensor, Ambient |

| 082 | Humidity sensor, Ambient |

| 083 | Temperature probe, Outside |

| 084 | Humidity sensor, Outside |

| 085 | Temperature probe, Blower |

| 086 | Circuit 1, Temperature sensor, Water condenser Outlet |

| 087 | Circuit 2, Temperature sensor, Water condenser Outlet |

| 088 | Temperature sensor, return or Mixing air |

| 096 | Low temperature, Water Condenser |

| 097 | High temperature, Water Condenser |

Troubleshooting

Please check below items before asking for maintenance.

Phenomenon: Indoor unit can’t receive remote controller’s signal or remote controller has no action.

Check items:

- Whether remote controller is within the signal receiving range?

- Whether there are obstacles?

- Whether remote controller is pointing at the receiving window?

- Is sensitivity of remote controller low; fuzzy display and no display?

- No display when operating remote controller?

- Fluorescent lamp in room?

Solution:

- Signal receiving range is 8m.

- Remove obstacles.

- Select proper angle and point the remote controller at the receiving window on indoor unit.

- Check the batteries. If the power of batteries is too low, please replace them.

- Check whether remote controller appears to be damaged. If yes, replace it.

- Take the remote controller close to indoor unit.

Phenomenon: No air emitted from indoor unit

Check items:

- Air inlet or air outlet of indoor unit is blocked?

- Under heating mode, indoor temperature is reached to set temperature?

- Heating mode is turned on just now?

Solution:

- Eliminate obstacles.

- After reaching to set temperature, indoor unit will stop blowing out air.

- In order to prevent blowing out cold air, indoor unit will be started after delaying for several minutes, which is a normal phenomenon.

Phenomenon: Air conditioner can’t operate

Check items:

- Power failure?

- Is plug loose?

- Air switch trips off or fuse is burnt out?

- Wiring has malfunction?

- Unit has restarted immediately after stopping operation?

- Whether the function setting for remote controller is correct?

Solution:

- Wait until power recovery.

- Reinsert the plug.

- Ask professional to replace air switch or fuse.

- Ask professional to replace it.

- Wait for 3min, and then turn on the unit again.

- Reset the function.

Phenomenon: Mist is emitted from indoor unit’s air outlet

Check items: Indoor temperature and humidity is high?

Solution: Because indoor air is cooled\rapidly. After a while, indoor temperature and humidity will be decrease and mist will disappear.

Phenomenon: Cooling ( heating) effect is not good

Check items:

- Voltage is too low?

- Filter is dirty?

- Set temperature is in proper range?

- Door and window are open?

Solution:

- Wait until the voltage resumes normal.

- Clean the filter.

- Adjust temperature to proper range.

- Close door and window.

Phenomenon: Outdoor unit has vapor

Check items: Heating mode is turned on?

Solution: During defrosting under heating mode, it may generate vapor, which is a normal phenomenon.

Phenomenon: ”Water flowing” noise

Check items: Air conditioner is turned on or turned offjust now?

Solution: The noise is the sound of \refrigerant flowing inside the unit, which is a normal phenomenon.

Phenomenon: Cracking noise

Check items: Air conditioner is turned on or turned offjust now?

Solution: This is the sound of frictioh caused by expansion and/or contraction of panel or other parts clue to the change of temperature.

Manual Pdf

- Unionaire Air Conditioner Error Codes - December 1, 2025

- Ameristar AC Error Codes and Troubleshooting - December 1, 2025

- Rheem Pool Heat Pump Error Codes - December 1, 2025

We have a error 3 what can I do

ı need your help

ı have an inverter mninisplit lennox model lxgıhhmd01815p4

code error f2

what the problem..

Kerr 18000 mini split heat pump.have code P4 what to do.

we have en E6 error message, what should we do?

Can’t find error code H5 on this list