TCL Technology – Telephone Communication Limited is a Chinese electronics company that was founded in 1981. Based in Huizhou, Guangdong the company designs, develops, manufactures, and sells televisions, mobiles, washing machines, refrigerators, air conditioners, and other small appliances. Voted as the world’s 25th largest consumer electronics producer in 2010, the company has come a long way.

TCL air conditioner global was established in 1999 and has been offering the world specialized residential and commercial air conditioning units since then. The company has made a great impact on the world, offering everything from basic to top-of-the-line technology that can be found in many homes and commercial air conditioning units.

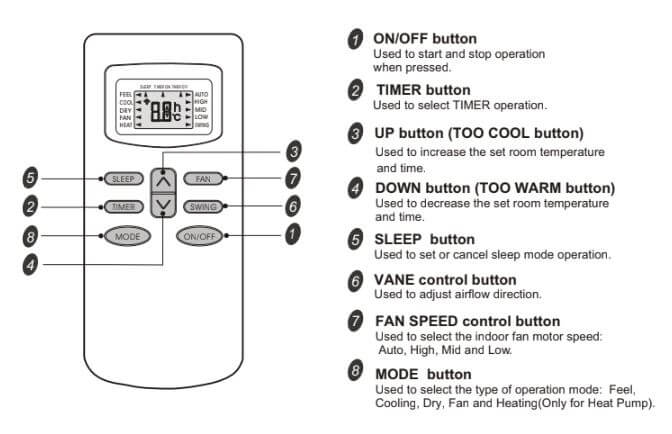

TCL is a widely recognized brand that has made its way to the top, becoming one of the best manufacturers and appliance distributors. That being said, there are times when customers have complained of facing technical issues regarding their air conditioning systems. To help you out we have listed down some of the most common error codes for TCL ACs. Start by noting down the error code, and match it using the list below. Once you have the error code you can easily work your way to the fix.

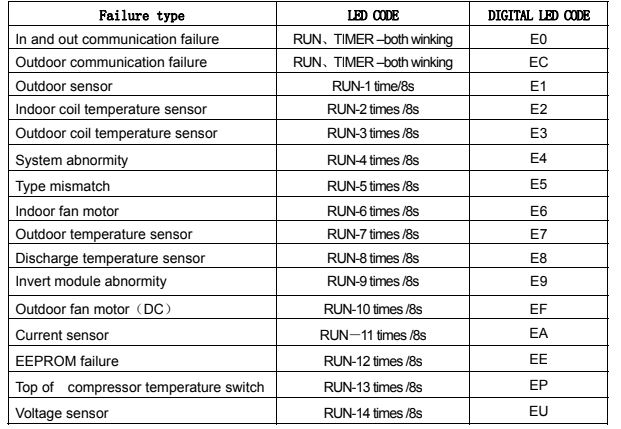

Protection and Fault Codes

E0: Indoor/outdoor communication fault

EC: Outdoor communication fault

E1: Room temperature sensor (IRT)

E2: Indoor pipe (coil) temperature sensor (IPT)

E3: Outdoor pipe (coil) temperature sensor (OPT)

E4: System abnormal

E5: Model configuration wrong

E6: Indoor fan motor fault

E7: Outdoor temperature sensor

E8: Exhaust temperature sensor

E9: Intelligent power module of drive and module fault

EF: Outdoor fan motor fault (DC Motor)

EA: Current sensor fault

EE: EEPROM fault

EP: Temperature switch fault (on top of the compressor)

EU: Voltage sensor fault

EH: Intake temperature sensor

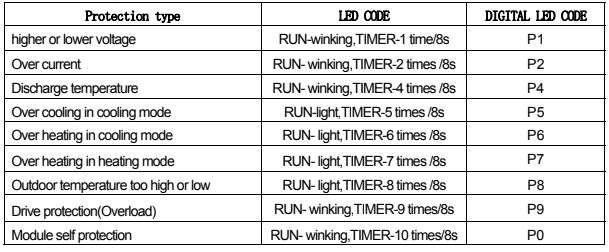

P1: Overvoltage / undervoltage protection

P2: Overcurrent protection

P4: Exhaust overtemperature protection

P5: Subcooling protection under cooling mode

P6: Overheating protection under cooling mode

P7: Overheating protection under heating mode

P8: Outdoor overtemperature / under temperature protection

P9: Drive protection (software control)

P0: Module protection (hardware control)

Protection and Failure Display

- When protection display is available, controller will show error code, digital LED shows error code and setting temperature by turns.

- If there is more than one failure, it will show at first that in front of the error list.

- Protection display function can be selected in hardware, and the default don’t display;

- To insure of in and out communist is credibility, the failures relate to outdoor unit will remain failure state for 2 minutes max after recovered.

- In all failures, only sensor failures don’t have to repower to cancel.

Protection Display Codes List

Outdoor Failure Display

There is a LED on outdoor power board, when compressor is running; it is normally light; when no feedback of signal to power board from compressor, it will wink by lighting 1s and going out 1s. If failures happened, it will light 0.5s, go out 0.5s, winking several times and go out 3s for a cycle to indicate failures.

| Wink time | Failure |

|---|---|

| 1 | IPM protection |

| 2 | Higher or lower voltage |

| 3 | Over current |

| 4 | Discharge temperature too high |

| 5 | Outdoor coil temperature too high |

| 6 | Drive abnormity |

| 7 | Communication abnormity with indoor unit |

| 8 | Compressor over heat(switch on top of compressor) |

| 9 | Outdoor air temperature sensor failure |

| 10 | Outdoor coil temperature sensor failure |

| 11 | Outdoor discharge pipe temperature sensor failure |

| 12 | Voltage sensor failure |

| 13 | Current sensor failure |

| 14 | IPM abnormity |

| 15 | Outdoor communication abnormity |

| 16 | DC fan motor no feedback |

| 17 | Defrosting |

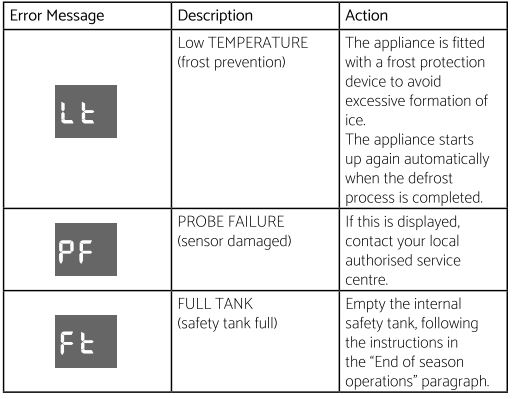

Portable AC Codes

This appliance has a self diagnosis system to identify a number of malfunctions. If an error message is displayed, please refer to the below table.

| Error Codes | Problem |

|---|---|

| Lt | Low Temperature ( frost prevention). Action: The appliance is fitted with a frost protection device to avoid excessive formation of ice. The appliance starts up again automatically when the defrost process is completed. |

| PF | Probe Failure ( sensor damaged). Action: If this is displayed, contact your local authorised service centre. |

| Ft | Full tank ( safety tank full). Action: Empty the internal safety tank. |

| AS | If the screen on the unit displays 'AS', the room temperature sensor has failed. Contact your Authorize Service Center. |

| ES | If the screen on the unit displays 'ES', the pipe temperature sensor has failed. Contact your Authorize Service Center. |

| P1 | If the screen on the unit displays 'P1', the water collection tank inside the unit should be full. If error repeats, contact your Authorize Service Center. |

Troubleshooting

Problem: Air conditioner will not start

Possible Causes:

- The air conditioner plug is not completely inserted into the electrical outlet.

- The fuse is blown or the circuit breaker has tripped.

- Power failure.

- P1 appears in the display.

- Room temperature is less than the set temperature.

Solutions:

- Make sure electrical plug is plugged completely into alive. properly grounded outlet.

- Replace the fuse or reset the circuit breaker. Make sure that there are no other appliances on the same circuit.

- If a power failure occurs, turn the power OFF. When power is restored, wait 3 minutes before restarting the air conditioner.

- The water collection tank is full. Drain the tank and reset your settings.

- This is normal. The air conditioner automatically shuts off when the room equals or is less than (Cool mode) or is more than (Heat mode)the set temperature. Adjust the temperature setting, if needed.

Problem: Air conditioner does not cool properly

Possible Causes:

- Airflow is restricted.

- The air filter is dirty.

- The room is very hot, or not enough time allowed for cooling.

- Cold air is escaping.

- Cooling coils have iced up.

Solutions:

- Make sure there is sufficient clearance around the air conditioner and that the air inlet and outlet are not blocked.

- Clean the air filter at least every two weeks.

- When first turned on, allow the air conditioner sufficient time to cool the room.

- Check for open furnace. floor registers cold air returns, open windows or doors.

- In especially cool, humid weather and when the air conditioner is running frequently or for extended periods, ice can form on the cooling coils, blocking air flow. It is normal, please adjust the temperature higher and High fan speed.

Problem: Air conditioner runs too often or too long

Possible Causes:

- Area to be cooled is too large for the air conditioner.

- Doors or windows are open.

Solutions:

- Consult your dealer for the air conditioner capacity necessary to cool the desired area.

- Make sure doors and windows are closed.

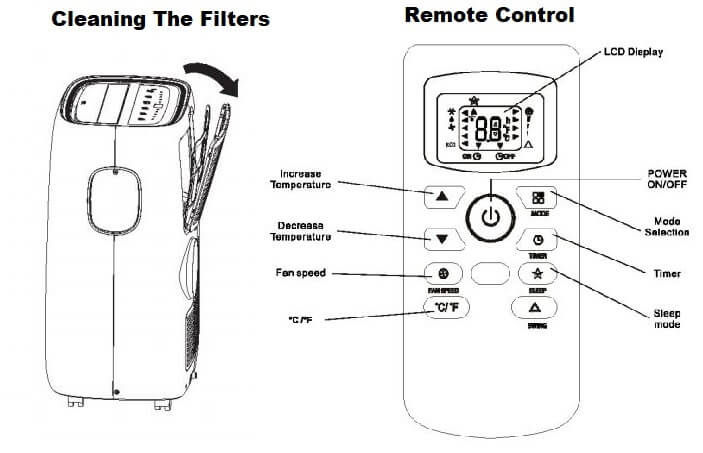

Cleaning The Filters

To keep your air air conditioner working efficiently, you should clean the filters every week of operation. Grasp the upper panel tab and take off the filter which behind the grill of the back panel as shown the right. Wash the filter using liquid dish washing detergent and warm water. Rinse filter thorough Gently shake excess water from the filter. Be sure filter is thoroughly dry before replacing. 0r, instead of washing you may vacuum the filter clean. Replace the filter after the filter is dry.

The ebinet and front may be dusted with an oiI-free cloth or washed with a cloth dampened in a solution of warm water and mild liquid dish washing detergent. Never use harsh cleaners, wax or polish on the cabinet front. Be sure to wring excess water from the cloth before wiping around the controls. Excess water in or around the controls may cause damage to the air conditioner.

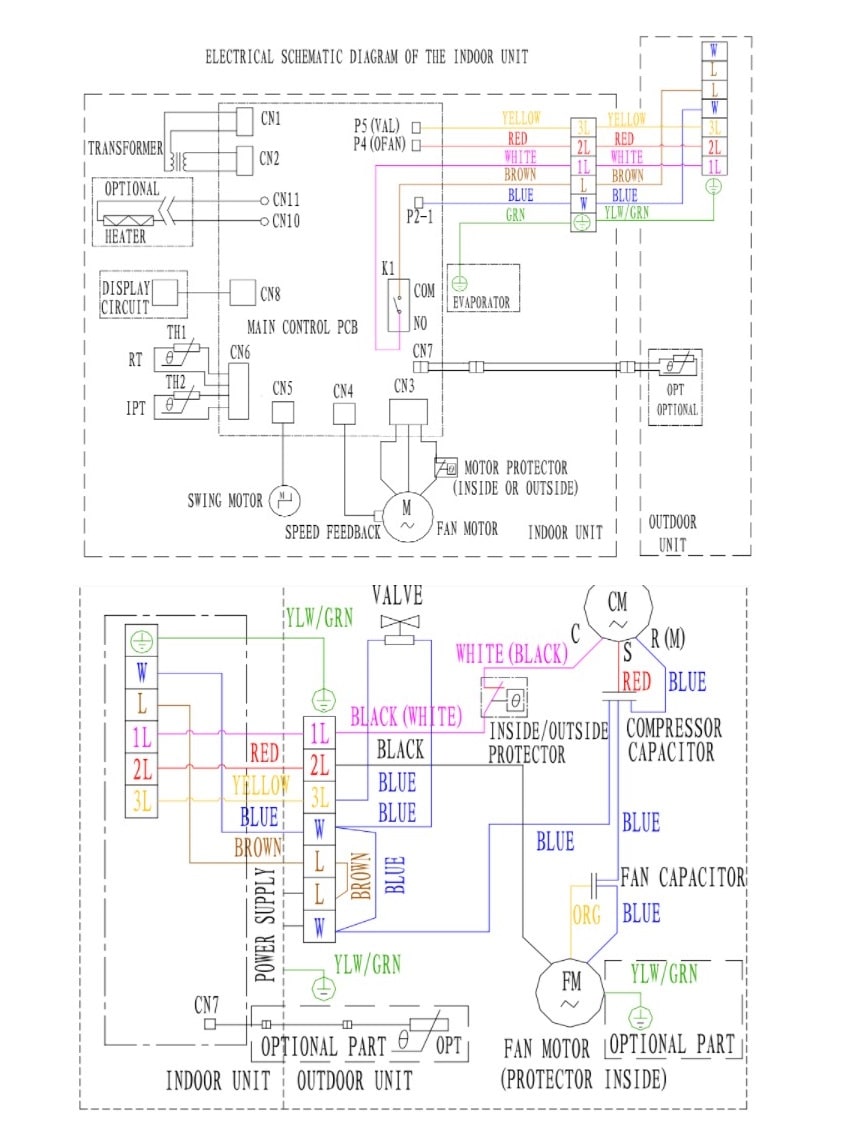

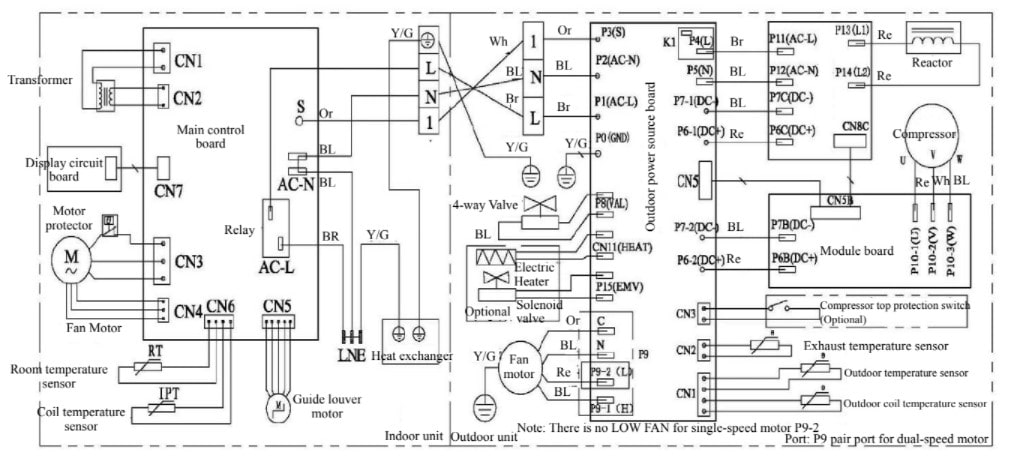

Wiring Diagram

Manual Pdf

Owner’s Manual Portable AC (Model TAC08-10)

Repair Guideline for TCL DC Inverter AC

Wall Mounted Split Type AC Service Manual

- Unionaire Air Conditioner Error Codes - December 1, 2025

- Ameristar AC Error Codes and Troubleshooting - December 1, 2025

- Rheem Pool Heat Pump Error Codes - December 1, 2025

I have E5code, what shall i do???

What to do error code E9

What to do with error code E9?

Hi i have a P6 problem?

What do i do?

I have error with E6,how can I resolve it?

please

the way how to solve Error E6.

I have the same problem Error E6 …. Please give us the solution

Hi I have a 48000 btu tcl split type that has anan error e5 please help me for remove thank u